Low-Spore Milk Production—The Mantra and its Benefits

Guest post: We are proud to introduce our guest blogger, David Blomquist. He is a well-known and respected consultant in the dairy and food processing industry. Read his full bio at the end of this article.

Low-spore milk production has financial benefits for many producers and processors. Fluid milk plants can reduce shelf-life issues by properly controlling thermoduric organisms and spore formers. In addition, plants selling concentrated dairy products or powder will get premium prices if they can produce low-spore products.

A facility’s ability to successfully produce low-spore milk can be due to many factors, most of which are in their direct control. The old dairy mantra can summarize these factors: “Keep it cold, keep it clean, keep it moving!”

“Keep it cold, keep it clean, keep it moving!”

Keep It Cold

Bacterial populations increase faster at warmer temperatures regardless of the organism type, spore, and non-spore formers alike. Ideally, processors should keep milk temperatures below 40o F (4.4o C).

Realistically, as the product moves through the supply chain, milk temperatures will often get up to 45o F (7.2o C), and if issues occur during distribution, even higher. Plants that cool milk upon receipt before pumping it into their storage silos will reduce its exposure to bacterial growth and, as a result, spore-forming bacteria.

Warming will occur in a silo that has just been cleaned. Properly chilled milk will cool the often-hot surfaces of a silo. If the silo is filled quickly, this temperature change will be minimal. However, if the milk was warm to start with (e.g., 45o F or 7.2o C) and the silo is left with a low volume of milk, the temperature will rise. Quickly filling a silo will minimize this growth.

Keep It Clean

Cleaning is the single most crucial factor. Biofilms start forming in as little as eight hours. This means any separators, cooling sections of a pasteurizer, and idle equipment will all be prime candidates for spores.

Raw milk tankers will start the growth cycle if they are not washed every time in the receiving bay. Research by QualiTru and Dr. Mansel Griffiths at the University of Guelph clearly showed that spore populations increased in the plant due to tankers not being washed after each unload in the plant. Read the research report.

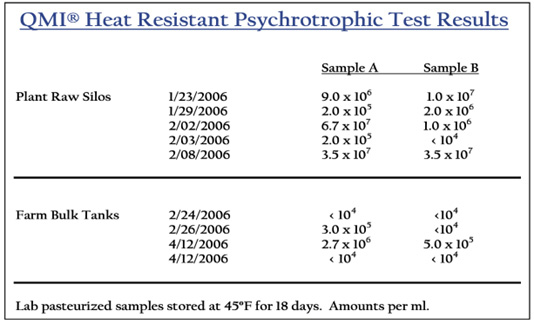

A significant source of heat-resistant psychrotrophs is ineffectively cleaned and sanitized raw milk handling equipment. A study conducted by QualiTru Sampling Systems (formerly known as QMI) showed that samples from farm bulk tanks have a lower instance of heat-resistant psychrotrophic bacteria than plant raw silo samples.

Properly washing any equipment requires adherence to the basic 4 step – 4-factor process:

- Rinse

- Wash

- Time

- Temperature

- Concentration

- Mechanical Action

- Rinse

- Sanitize

Your sanitation team and supplier of chemicals should be able to assist you in making sure the washing protocol is proper and effective.

Keep It Moving

If you have a good cold supply of milk and good clean equipment, you can still lose the battle if you do not rotate the milk quickly. Raw silos should be emptied as soon as possible. The Pasteurized Milk Ordinance (PMO) allows a silo to store milk for up to 72 hours. While this is legal, it will not result in low spore products.

Shortening storage time prior to pasteurization will go a long way in providing low spore results. If a plant can rotate silos daily, that is optimal. If not, reducing the storage time to 48 hours or less is needed. Longer storage times will result in higher counts.

Measuring Results

Ideally, you will be able to measure your successes or failures with microbiological test results. Inline samples need to be taken at critical points, such as out of a raw storage silo, just after pasteurization, or into a filler.

If a problem exists, these samples would be taken at start-up and every four hours during the production run. At a minimum, samples can be taken from the high temperature short time (HTST) pasteurization at the beginning, middle, and end of a run. Samples can be tested for organisms of concern (e.g., spore formers), but a simple standard plate count often indicates issues.

Spores will continue to be a concern for dairy plants in the future. As discussed in this blog, meticulously addressing the details of the proper operation of a facility can help ensure the production of low-spore milk.

Additional research materials:

Have questions about aseptic and representative sampling for dairy plants?