Mastitis in Dairy Cows: The Role of Inline Sampling in Testing and Prevention Programs

Effective mastitis management is critical for maintaining herd health and ensuring high milk quality. The following is information on the causes, economic impacts, symptoms, testing, prevention, and treatment of mastitis in dairy cows, emphasizing the role of inline sampling for improving detection and management.

Causes of Mastitis in Dairy Cows

Mastitis in dairy cows is characterized by the inflammation of the mammary gland and udder tissue, usually due to bacterial infections that enter the udder through the teat canal, causing inflammation and reduced milk production. Common pathogens include Staphylococcus aureus, Streptococcus agalactiae, and environmental bacteria such as coliforms. Factors contributing to mastitis include poor milking hygiene, contaminated milking equipment, heat injury to the udder, and environmental conditions like wet bedding and manure contamination. (Jones et al., 2009) The integrity of the teat end is crucial, as any damage can facilitate bacterial entry and subsequent infection.

According to the 2011 edition of Dairy Production Medicine, more than 90% of mastitis cases are related to infectious pathogens naturally occurring in the environment and are highly contagious. Therefore, proper monitoring systems and early detection and identification of pathogens are essential to prevent contraction.

The Economic Impact of Mastitis on the Dairy Industry

Mastitis significantly impacts the dairy industry economically, with estimated annual costs ranging from $1.7 to $2 billion in the United States alone. These costs are attributed to reduced milk yield, discarded milk, veterinary treatments, and increased culling rates. Additionally, the presence of mastitis can lead to lower milk quality, affecting cheese yield and other dairy products.

“The NMC (National Mastitis Council) estimates that mastitis costs dairy producers in the U.S. over $2 billion annually. Thus, mastitis continues to be one of, if not, the most significant limiting factor to profitable dairy production in the U.S. and throughout the world.”

Recognizing the Symptoms of Mastitis: From Clinical to Subclinical

Mastitis manifests in two forms: clinical and subclinical. Clinical mastitis is characterized by visible symptoms such as swelling, redness, heat, and pain in the udder, along with abnormal milk appearance. Subclinical mastitis, however, is more insidious. It presents no visible symptoms but is detectable through elevated somatic cell counts (SCC) and reduced milk production. (Jones et al., 2009) Monitoring SCC allows dairy farmers to identify potential udder health issues early on.

The standard unit for expressing SCC is cells per milliliter (cells/ml) of milk. In the US, the legal standard is set at 750,000 cells/ml. Beyond this threshold, milk may be considered of lower quality and could be subject to penalties or rejection for processing. Infected cows with higher SCC will also produce less milk. SCCs are relatively low in healthy cows, usually in the range of 50,000 to 200,000 cells/ml. According to the Council for Dairy Cattle Breeding (CDCB), herd milk in 2021 averaged 179,000 somatic cells/ml of milk, and 4% of US herds had SCC of more than 750,000. Variation in SCC can occur based on factors such as breed, age, and lactation stage.

Mastitis Testing: Techniques and Technologies

Effective management of mastitis in dairy cows relies on early and accurate detection. Traditionally, bulk tank analysis and individual animal cultures, and milk analysis have been the strategies to identify mastitis-causing organisms and determine SCC on dairy farms.

Both methods have their limitations. Positive bulk tank analysis requires the costly dumping of entire bulk tank loads. The expensive screening of individual cultures and removing infected cows from the herd are significant drawbacks of this approach.

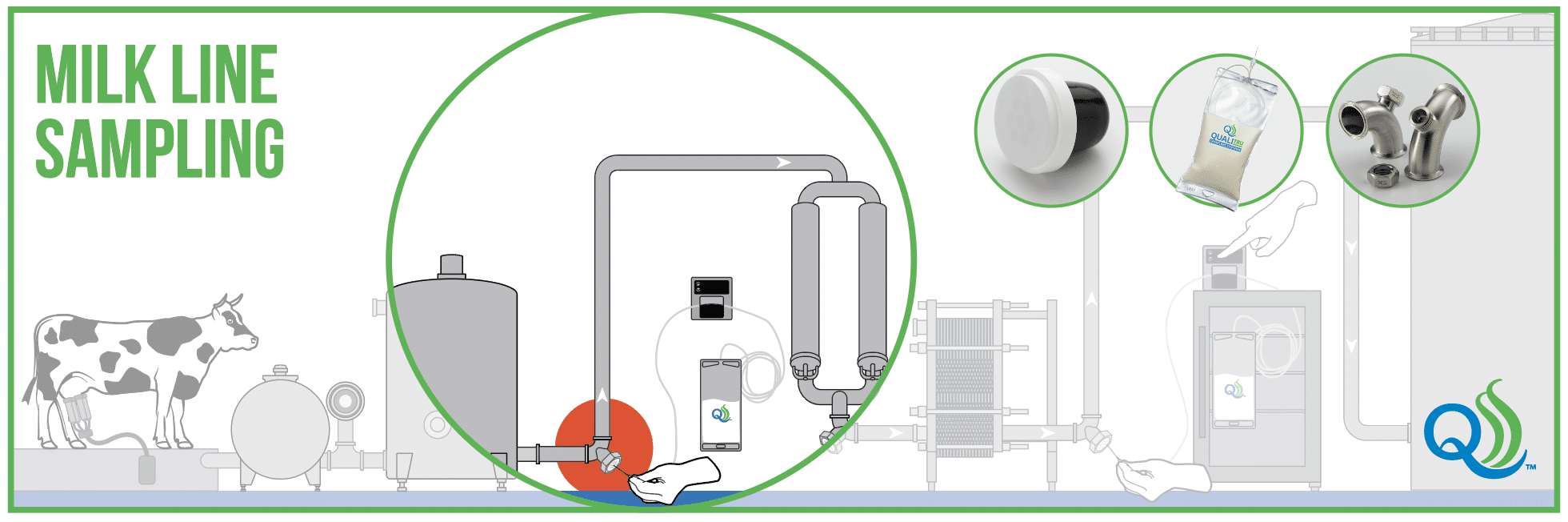

A more cost-effective strategy is string sampling which collects a representative inline sample of a group of cows during the milking process. Test results on these samples are helpful in determining whether milking machines are clean and employees adequately sanitize udders before attaching the milking unit to the cow. Results can also help monitor the herd for mastitis by identifying and isolating infected cows.

In 2002, Godden, et al. conducted a validation study at the University of Minnesota and reported there are four potential benefits to string sampling as part of a routine cow health and milk quality monitory program:

- An inline sampling program allows producers to monitor different groups of cows within the herd.

- An inline sample may provide greater test sensitivity for detecting pathogens because it allows sampling relatively small groups of cows at a time rather than the whole herd or large groups.

- Milk line sampling may be used to narrow the search for cows that are infected with contagious mastitis pathogens, stating, “If the culture of milk…from individual groups could be used to narrow the search to one or two positive groups, this would have potential to save the producer considerable time, labor, and expense.”

- A very useful prospect for using milk line sampling is to use counts of environmental bacteria, such as coliforms or Streptococcus non-agalactiae to monitor changes in environmental sanitation and milking management.

Proactive Prevention of Mastitis: Keeping Mastitis at Bay

Preventive measures are crucial for controlling mastitis. Maintaining stringent hygiene practices, such as regular cleaning of milking equipment and proper cow preparation before milking, can significantly reduce infection rates. Ensuring a clean and dry environment for cows, especially post-milking when the teat canal is still open, is also vital. (Jones et al., 2009) Additionally, teat dips are effective in reducing the potential for infection. Employee training on mastitis detection and management protocols further supports prevention efforts.

Keeping a clean environment will play a huge part in the onset of mastitis. This is especially true of the environment cows are milked in and return to before their teat ends fully close and replug after milking.

Effective Treatment Strategies for Mastitis in Dairy Cows

Mastitis treatment typically involves the use of antibiotics to combat bacterial infections. However, the choice of treatment depends on the pathogen involved and the severity of the infection. Treatment plans should be discussed with your veterinarian. Early detection and appropriate treatment are essential to prevent the spread of infection and minimize economic losses.

Inline Sampling for Udder Health

Detecting and managing mastitis in dairy cows involves understanding its causes, recognizing its economic impact, identifying symptoms early, and implementing effective testing and prevention strategies. Inline sampling plays a critical role in enhancing mastitis detection and improving overall herd health, ultimately supporting the production of high-quality milk.

Do you have questions about inline sampling on dairy farms for udder health? Call us at (651) 501-2337 or click below for more information!

References

Jones, G. M., & Bailey, T. L. Jr. (2009). Understanding the Basics of Mastitis. Virginia Cooperative Extension. Produced by Communications and Marketing, College of Agriculture and Life Sciences, Virginia Polytechnic Institute and State University. Retrieved from https://www.ext.vt.edu

Godden, S., Bey, R., Farnsworth, R., Reneau, J., & LaValle, M. (2002). Field validation of a milk line sampling device for monitoring milk quality and udder health. Journal of Dairy Science, 85(6), 1468-1475. https://doi.org/10.3168/jds.S0022-0302(02)74215-X