Sampling for Microbes in Beer

Crafting the perfect beer is an art form that faces serious risks from invisible threats – microbial contaminants hidden within the brew. These microscopic invaders, if left unchecked, can transform a delightful beverage into a spoilage nightmare. It is essential for any brewery dedicated to quality and consistency to recognize and combat these threats.

Microbes in Beer

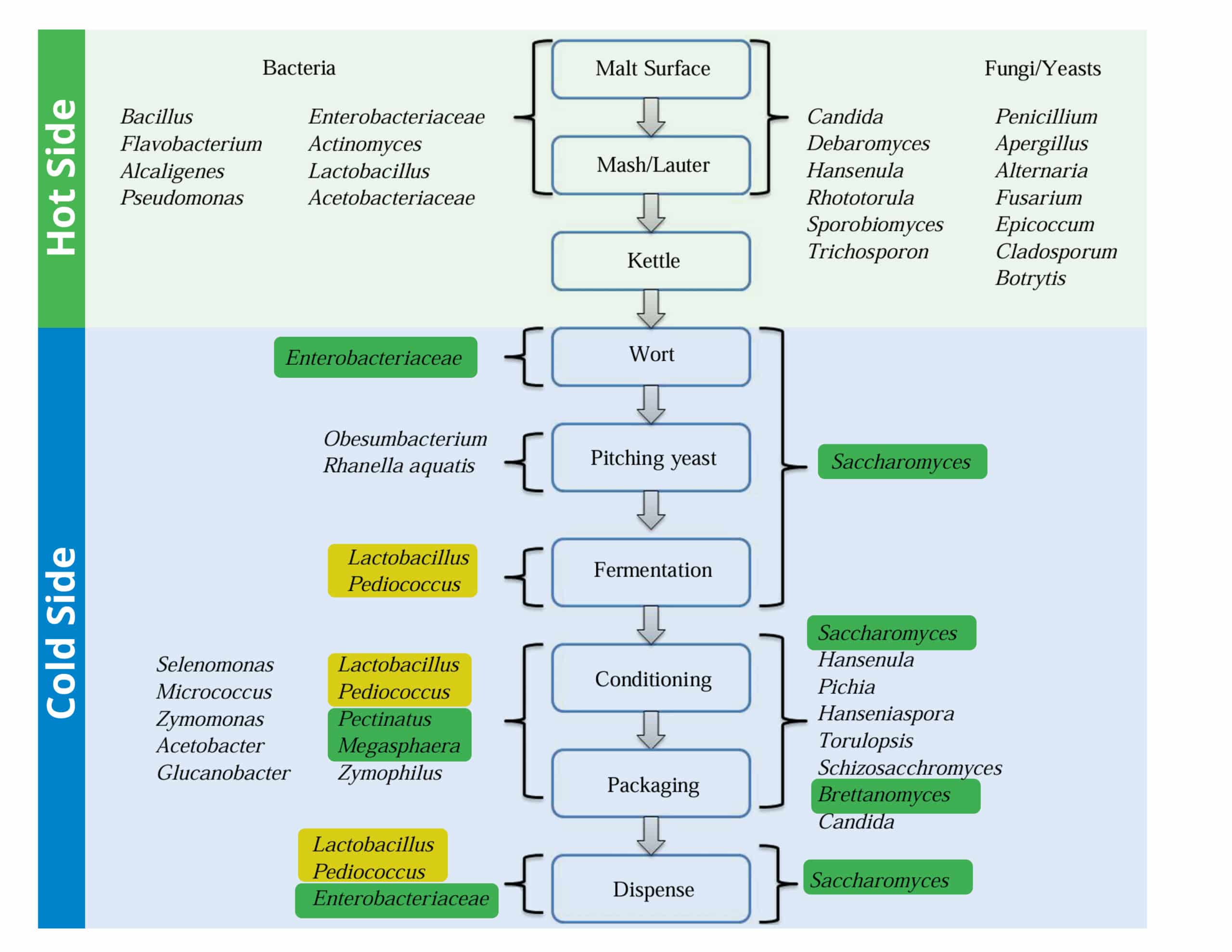

Microbial contamination in beer can arise from various sources and can have a profound impact on the quality, flavor, and safety of the product. The most common beer contaminants that breweries should sample and test for are:

- Lactic Acid Bacteria (LAB): These are the most prevalent beer spoilers, responsible for 60-90% of contaminations. LAB, including Lactobacillus and Pediococcus species, can survive in beer due to their resistance to hops and can produce lactic acid, making the beer sour and giving it a turbid (cloud or muddy) appearance. They are notable for their strong resistance to hop iso-alpha acids and can spoil the beer by producing off-flavors like diacetyl, which gives a buttery taste.

- Acetic Acid Bacteria: This group includes Acetobacter and Gluconobacter, which are known to oxidize ethanol into acetic acid, imparting a vinegary taste to the beer. They are less common than LAB but can spoil beer if aerobic conditions prevail post-fermentation.

- Wild Yeasts: Non-Saccharomyces yeasts like Brettanomyces can contribute to beer spoilage by producing phenolic (clove-like, medicinal, smoky, or “band-aid”) off-flavors. While some brewers use Brettanomyces intentionally in specific beer styles, unintended contamination can lead to undesirable flavors and excessive carbonation.

- Enterobacteriaceae: These are typically wort spoilers rather than beer spoilers because they don’t survive well in the alcoholic, hoppy environment of finished beer. However, they can spoil the wort during brewing, leading to off-flavors like diacetyl and increased levels of dimethyl sulfide (DMS), which can impart a cooked corn aroma.

- Pectinatus and Megasphaera: These gram-negative bacteria are increasingly encountered in breweries and can produce off-flavors like hydrogen sulfide (rotten egg smell) and butyric acid (rancid butter taste). They are anaerobic and thrive in the beer packaging phase where oxygen levels are low.

The QualiTru Sampling System: A Shield Against Microbes in Beer

The QualiTru sampling system is designed for process monitoring and microbial contamination control, which are crucial in a field where microbial stability is essential for product consistency and flavor profile. Here’s how the QualiTru sampling system complements the measures used to detect the top beer contaminants:

- Enhanced Detection of Lactic Acid Bacteria and Other Spoilers: The QualiTru system enables accurate and representative sampling, which is vital for detecting lactic acid bacteria, wild yeasts, and other microorganisms responsible for beer spoilage. By allowing for aseptic and representative sampling, breweries can more effectively monitor the presence of these contaminants and take timely corrective actions.

- Improved Quality Control and Consistency: Consistent quality is key in brewing. The QualiTru sampling system allows for ongoing monitoring of the brewing process, helping to ensure that the beer maintains its intended flavor profile, free from off-flavors caused by unwanted microbial activity. This level of control is crucial for preventing batch losses and maintaining brand reputation.

- Early Detection of Contamination: Early detection of microbes in beer can save significant resources and prevent the distribution of spoiled product. The QualiTru sampling system facilitates early detection, enabling brewers to address contamination issues before they escalate, thereby reducing the risk of large-scale spoilage and recalls.

- Streamlined Process and Efficiency: The system is designed for ease of use and efficiency, allowing for quick and easy sampling without interrupting the brewing process. This can lead to improved workflow, reduced downtime, and overall greater efficiency in brewery operations.

- Supports Proactive Quality Assurance: By integrating the QualiTru sampling system, breweries can adopt a proactive approach to quality assurance rather than a reactive one. Regular sampling can help identify trends and potential issues before they become significant problems, supporting continuous improvement and optimization of the brewing process.

Incorporating a QualiTru sampling system, such as the QualiTru TruStream Ports and TruStream Septa, into brewery operations can significantly enhance the ability to control and monitor microbial contamination, thereby protecting the integrity of the beer and ensuring consumer satisfaction. For breweries, implementing such a system means safeguarding the quality of their product and reinforcing their commitment to excellence and reliability in the eyes of their customers.

Visit our Breweries page for a detailed exploration of application sites for the QualiTru sampling system in breweries and the benefits they provide.

Safeguarding Beer Quality: The Proactive Power of QualiTru

The invisible threats of microbial contamination are a significant concern in the brewing industry, but they can be effectively managed with the right tools and strategies. The QualiTru sampling system stands out as a premier solution for breweries aiming to uphold the highest quality standards, ensuring that every sip is a testament to their commitment to excellence. Embrace this innovative approach to safeguard your brews, and toast to the success and longevity of your beer’s superior quality.

Contact us to learn more about the QualiTru sampling system and how to integrate it into your brewing operations.

Have questions about QualiTru sampling systems and beer contamination control?

Need a quote? We’ll respond to

your request quickly.

Looking for one of our global distribution partners near you?

Citations:

Bokulich NA, Bamforth CW. 2013. The Microbiology of Malting and Brewing. Microbiol Mol Biol Rev 77:.https://doi.org/10.1128/mmbr.00060-12