Representative Sampling for Butterfat Verification

Why is representative sampling for butterfat verification important?

Because reliable data equals accurate payment!

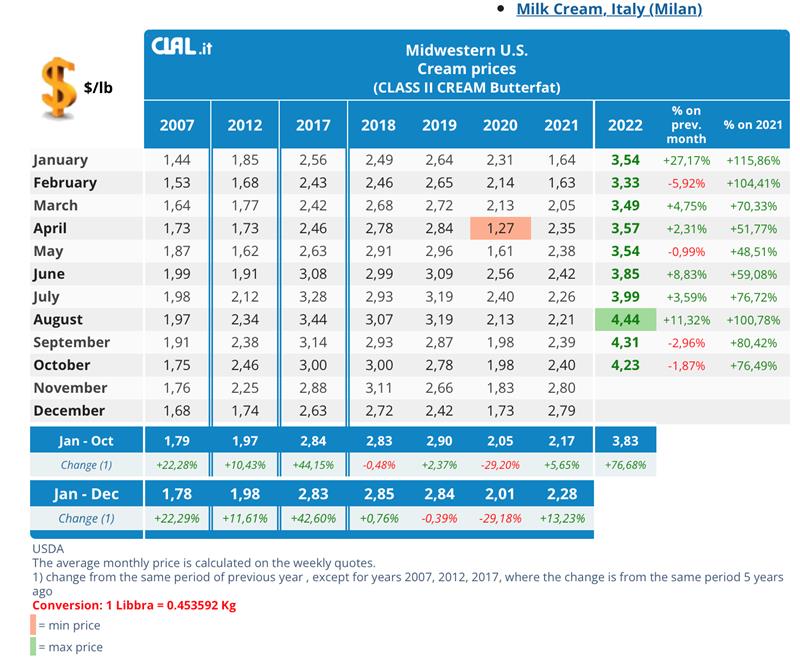

Butterfat percentages in milk have been on the rise over the last decade, along with a substantial upward trend for butterfat pricing. That’s great news for farmers. It also raises the stakes regarding the accuracy and reliability of the data upon which butterfat payments are based. With current concerns over rising feed prices and overall inflation, the importance of accurate butterfat pricing is elevated to a new level. Accurate measurement of butterfat allows dairy farmers to capture premium payments and increase profitability. Now is the time to make sure farmers and cream producers are receiving true and reliable payments for every load.

What does unreliable data suggest about sample integrity?

Since the value of cream is largely in the butterfat it contains, accuracy in sampling and testing is critically important. As in the example below from a cream plant in Ireland, if you are not collecting reliable data, you are most likely not receiving accurate payment.

Ireland cream plant struggles with collecting reliable and consistent testing data

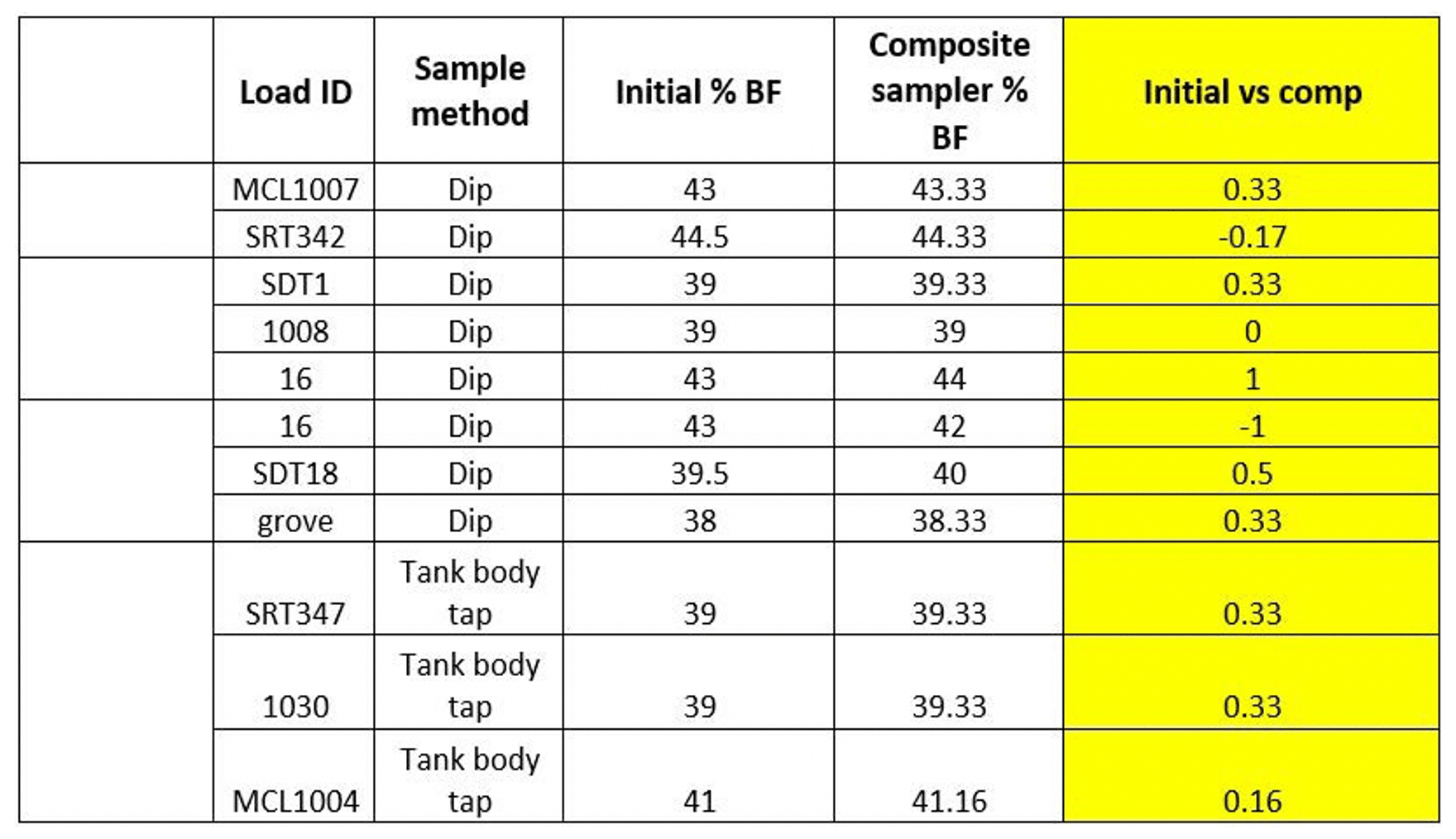

A cream plant in Ireland was struggling with inconsistent and unreliable data related to butterfat testing. The cream was sampled prior to unloading with a variety of methods, depending upon the type of tanker used. Samples were dipped from the top, taken from sample taps on the body of the tanker, or from sample taps on the discharge pipework. The variabilities in sampling methods and testing data led to questions regarding sample integrity and whether co-op members were receiving accurate payments for butterfat.

Can representative or composite sampling improve the reliability and consistency of testing data?

Looking for a more reliable sampling method, the plant installed a QualiTru system. QualiTru’s simple-to-use sampling system utilizes a peristaltic pump that draws liquid samples into a TruStream Collection Unit, providing a continuous flow for collecting representative samples of cream during the entire load discharge time.

The composite samples were used to test the percentage of butterfat and compared to the results from cream samples collected by dipper or from taps on the side of the tanker trucks from eleven tanker loads. Eight of the eleven loads had a higher percentage of butterfat with the composite samples, compared to the initial butterfat readings using the other sampling procedures. One load did not show any difference. The maximum difference was 1% increase with the composite sample.

When using representative sampling for butterfat verification, most loads had a butterfat increase between 0.33-0.5% when compared to the other sample results. While this butterfat percentage per load variance is small, the cumulative financial impact is significant. In this small study, the calculated advantage for the farmers would be approximately 50,000 euros or $50,000 annually.

Accurate butterfat testing impacts your bottom line!

Between 2000 and 2012, the average butterfat tests in the upper Midwest hovered between 3.7% and 3.8%. That number trended upward quickly for the next ten years with 2021 seeing an average milk fat increase from 3.75% to over 4.0% for the first time. The trend increases continued into 2022 with an average bulk tank fat test of 4.25% in January. (Source: Cornell University)

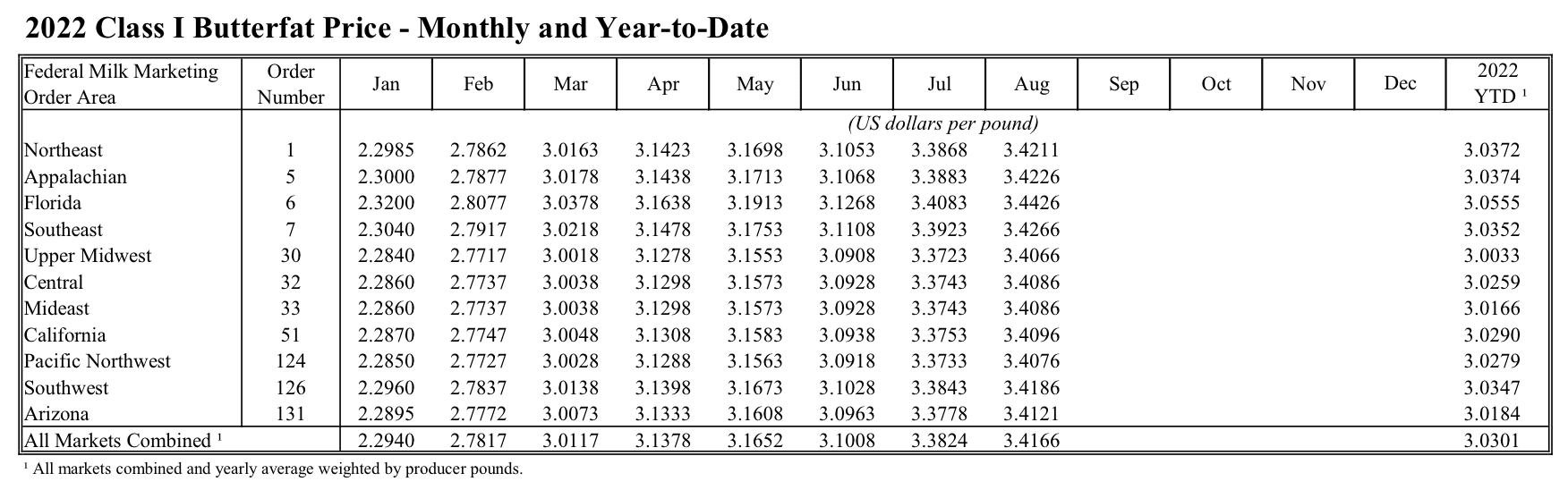

According to the Federal Milk Marketing Order, monthly pay prices for butterfat prices continue to rise in 2022 — up over a dollar a pound since January 2022!

Your test result is only as accurate as your sample.

Representative sampling for butterfat verification using the QualiTru sampling system helped reduce variability in butterfat testing results, providing more reliable data. Overall, the comparisons indicate that this sampling method helps ensure more accurate and reliable butterfat data for completing payment agreements with co-op members.

Beyond butterfat verification…

With QualiTru’s simple-to-use system, samples are drawn aseptically, meaning the sampling equipment is sterile and the sampling process itself is designed to eliminate the potential introduction of external contaminants, which is ideal for monitoring somatic cell counts (SCC) for premium and bonus payments. Our related blog post, Somatic Cell Counts (SCC) Impact on Dairy Farmers, discusses how implementing routine string sampling as part of your process management strategy for monitoring SCC can lead to increased profits.

Whether it be for milk or cream, receiving accurate and reliable component payments has never been more important. With the current trend in rising butterfat prices, you need assurance that you are being fairly compensated. Accurately measuring components using the QualiTru aseptic and representative sampling system allows dairy farmers to capture premium payments and increase profitability.

Here are additional resources on our website that will help you learn more about representative sampling.

Additional Resources:

- Related blog posts:

Somatic Cell Counts (SCC) Impact on Dairy Farmers

Using Preliminary Incubation Count for Measuring Raw Milk Quality - Training

Site application schematics

Standard Operating Procedures (SOPs) - Video

Have questions about string or aseptic and representative liquid sampling? Ask our experts for a free consultation or call us at 651-501-2337. We love troubleshooting issues and using analytics to solve complex problems to provide customer-focused insight.