Controlling Yeast in Cheese Production: Strategies for Quality Assurance

Yeast contamination is of minimal concern in fluid milk production, but its impact can be significant in cheese and fermented dairy products where unwanted yeast may alter flavor, texture, and overall product quality. Understanding the growth parameters and spoilage mechanisms of yeast in cheese production is key to developing effective control strategies. Process monitoring strategies play a pivotal role in ensuring the quality and safety of cheese products.

Understanding Molds and Yeast in Cheese Production

In cheese production, molds and yeasts play significant conflicting roles in enhancing and compromising product quality. In certain specialty cheese processes, yeasts play a pivotal role by contributing to the development of distinct flavors and textures. For instance, in artisan or probiotic cheeses, Saccharomyces cerevisiae may be used alongside lactic acid bacteria to enrich the product’s texture, flavor, and nutritional profile. Similarly, Debaryomyces hansenii and Geotrichum candidum are yeasts used in brined and surface-ripened cheeses, such as feta, Saint-Nectaire, and Brie, to promote flavor, rind development, and soft, creamy texture. Molds, such as Penicillium roqueforti in blue cheese and Penicillium camemberti in Camembert, also add unique flavors and textures through their enzymatic actions on proteins and fats.

However, undesirable mold and yeast contamination in cheese can lead to spoilage, affecting the visual appeal, flavor, and aroma. Effective management of mold and yeast populations through rigorous hygiene practices, temperature control, and continuous monitoring of raw materials and processes is crucial for maintaining cheese quality. In particular, yeast contamination requires diligent control to prevent spoilage and ensure product integrity.

What is yeast?

Yeasts represent a diverse group of unicellular fungi with significant implications for industry, research, and ecology. Their ability to ferment sugars, their genetic tractability, and their role in various ecosystems underscore their importance in being both beneficial and potentially harmful.

Yeast Growth Parameters

Yeasts are a diverse group of single-celled fungi that can thrive in various environments, including cheese. Key growth parameters influencing yeast proliferation include:

- Nutrient Availability: Milk provides an ideal environment for yeast growth due to its rich nutrient content. Although yeasts have limited ability to metabolize lactose, many can produce lactase, an enzyme that breaks lactose down to its constituent sugars, glucose and galactose. These simple sugars can be further metabolized by yeast for energy production.

- pH Levels: Yeasts prefer slightly acidic to neutral pH levels, typically ranging from pH 4 to 6. Some yeasts, such as Candida spp., can tolerate a broader pH range.

- Temperature: Optimal growth temperatures for most yeast species range between 25°C and 30°C. However, specific strains may prefer different temperatures, with some capable of growing at refrigeration or higher temperatures.

- Oxygen Requirements: Yeasts can be obligate aerobes, needing oxygen for growth, or facultative anaerobes, capable of growing with or without oxygen.

- Osmotic Pressure: Yeasts can tolerate high osmotic pressures, giving them a competitive advantage over bacteria in environments with high salt or other solute concentrations.

- Water Activity: Yeasts can grow in low-moisture environments, with some species thriving at water activity levels as low as 0.61.

Spoilage Mechanisms of Yeast in Cheese Production

Yeasts contribute to spoilage in cheese through various mechanisms, leading to off-flavors, gas production, and changes in texture:

- Off-Flavors: Certain yeast strains produce volatile compounds during fermentation, resulting in undesirable fruity or vinegar-like aromas and flavors. This is particularly common in cheeses with high sugar content.

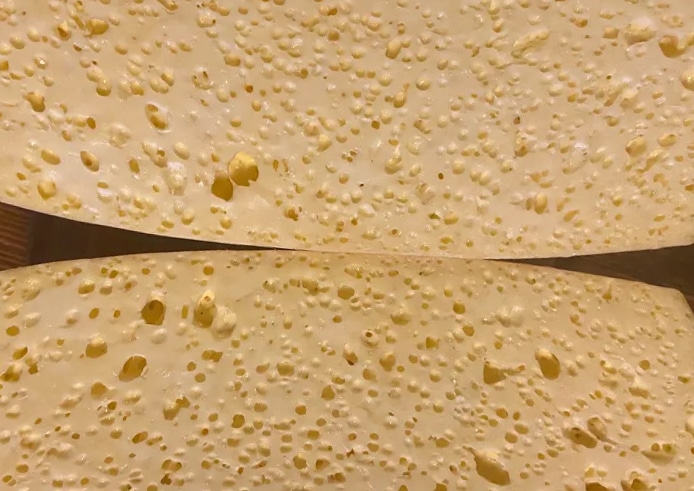

- Gas Production: Some yeasts produce carbon dioxide and other gases during fermentation, causing bloating or swelling of the product or packaging. This defect is most often seen in soft cheeses.

- Texture Changes: Yeasts can influence the texture of cheese by producing extracellular enzymes that alter the structure of proteins and fats. These defects are of particular concern in soft and semi-soft cheese, where yeasts may cause sliminess or structural breakdown.

- Ropy or Stringy Texture: Certain yeasts, particularly Candida spp., produce polysaccharides that create a ropy or stringy texture. This defect is often observed in cultured dairy products like yogurt and buttermilk.

The Role of Process Monitoring in Controlling the Contamination of Yeast in Cheese Production

Process monitoring plays a crucial role in controlling bacterial and yeast contaminants in dairies by enabling early detection of potential issues and isolating potential sources of contamination, allowing for timely corrective action. Here’s how process monitoring contributes to the control of bacterial and yeast contaminants in dairies:

Early Detection and Quality Assurance: Process monitoring is essential for the early detection of yeast contamination in cheese. Regular sampling and microbiological analyses of raw materials, intermediate products, and finished goods help identify potential issues before they escalate. Continuous monitoring ensures that cheese products meet specified quality standards, allowing for timely corrective measures when deviations occur.

Hygiene Validation and Fermentation Control: Maintaining a hygienic processing environment is essential for minimizing yeast contamination. Regular monitoring of surfaces, equipment, and utensils validates the effectiveness of cleaning and sanitation procedures. Additionally, monitoring pH and temperature during processing helps maintain optimal conditions, preventing yeast overgrowth and ensuring product quality.

Real-Time Data Analysis and Risk Mitigation: Implementing data logging systems enables real-time data collection throughout production. Trend analysis of this data can identify potential sources of contamination, allowing for targeted interventions. Establishing critical control points (CCPs) based on process monitoring data helps mitigate contamination risk at specific production stages.

Advanced Analytical Techniques: Advanced molecular techniques, such as PCR and DNA sequencing, provide higher resolution in detecting specific bacterial and yeast strains. This precision allows for more effective control measures and targeted interventions, enhancing the overall quality and safety of cheese products.

Continuous Improvement: Process monitoring creates a feedback loop for continuous improvement. Insights gained from monitoring data inform adjustments to processing parameters, hygiene practices, and quality control measures, ensuring the consistent production of safe and high-quality cheese products.

Safeguarding Cheese Quality with Proactive Yeast Control

Controlling yeast contamination in cheese production requires a comprehensive understanding of yeast growth parameters and spoilage mechanisms. Process monitoring is critical in maintaining product quality and safety, enabling early detection, hygiene validation, and real-time data analysis. By implementing advanced analytical techniques and continuous improvement strategies, cheese producers can effectively manage yeast contamination, ensuring the production of high-quality, safe cheese products.

Contact us at (651) 501-2337 for more information or complete this form to have one of our experts contact you to discuss how QualiTru Sampling Systems can help your cheese production facility maintain high quality and safety standards. Our advanced sampling systems and expertise in process monitoring can provide you with the tools needed to effectively control yeast and bacterial contamination.

Have questions about using QualiTru Sampling systems for quality control in cheese production?