Raw Milk Testing for the 21st Century: Key Parameters for Achieving High Quality

The quality of processed dairy products is inextricably tied to the quality of raw milk at production, and throughout pre-processing storage and handling. Pasteurization, while quite literally a lifesaver, is no magic bullet when it comes to improving quality. As domestic and international markets for US dairy products evolve, expectations of increasing shelf life are pushed to the limits, and consumers have a seemingly endless parade of non-dairy alternatives at their fingertips, the role of raw milk testing in achieving the goals of the dairy community becomes increasingly important.

Raw milk quality testing is certainly not new news; in fact, it’s one of the oldest forms of food and beverage testing there is. With rapidly changing expectations for processed dairy products, and shifts in production practices over the last two decades, we must look at raw milk quality with a new, contemporary viewpoint.

Pasteurized dairy quality is directly impacted by raw milk microbiological, chemical and physical, and flavor and odor parameters.

~Dr. Nicole Martin

Raw Milk Testing Parameters for Evaluating Key Microbial Factors Impacting Dairy Quality

There are a number of raw milk quality parameters that affect finished product quality: microbial, chemical and physical, and flavor and odor. From a microbial perspective, there are just a few groups of organisms that when present in raw milk at sufficient levels can cause processed dairy product quality defects:

- Psychrotolerant, or cold tolerating, enzyme producing bacteria. The most common of these organisms is Pseudomonas, and other closely related bacteria. Pseudomonas grows quickly at low temperatures and at high concentrations; typically, around a million cells/mL, can produce heat stable enzymes. These enzymes can then go on to survive pasteurization, even ultra pasteurization (UP) or ultra-high temperature (UHT) processing, ultimately causing flavor, odor, and texture defects in cheese, extended shelf life fluid milk, and other dairy products.

- Spore-forming bacteria. Spore-forming bacteria are a unique group of bacteria that form a structure called an endospore, or just spore, when they are under stress in their environment. Spores are resistant to heat, chemicals, low moisture, and other conditions that would be otherwise detrimental to the bacteria. Due to this resistance, spores can survive pasteurization and other processing conditions that are used in the dairy industry. Therefore, when spores, which are found in the natural environment in places like soil and water, transfer into raw milk during milking, they can ultimately go on to cause spoilage in fluid milk, cheese, and even in reconstituted powder products.

- Select non-spore-forming heat resistant bacteria. Often called thermoduric bacteria, some non-spore-forming bacteria are also able to survive mild to moderate heat treatments and go on to cause quality issues in finished products such as fluid milk, cheese, and others. While there is a somewhat large group of thermoduric bacteria that can be found in raw milk, most do not survive high-temperature, short-time (HTST) pasteurization, the most commonly applied pasteurization process used in the United States. An example of a non-spore-forming thermoduric bacteria that survives HTST pasteurization and is able to grow in refrigerated dairy products is Microbacterium.

Raw Milk Testing Parameters for Evaluating Key Chemical and Physical Factors for Quality Control

From a chemical and physical perspective, the most important factor in raw milk is the somatic cell count. A great deal of research has been done to demonstrate that high somatic cell count in raw milk reduces cheese yield, increases flavor and odor defects in cheese and fluid milk during storage, and may cause gelation and sedimentation defects in UP and UHT fluid milk under certain conditions. Elevated levels of free fatty acids (FFA) are also a concern, as they can impact milk’s functional properties, like foaming, and lead to flavor defects that affect the overall quality of dairy products.

Finally, an often-overlooked quality parameter is the flavor and odor profile of raw milk. Fluid milk is quite susceptible to flavor and odor defects that are the result of production practices, raw milk handling, or storage. These defects are typically categorized by their origins, namely:

- Absorbed. Absorbed odors and flavors include those that were inhaled by the animal from the environment, such as strong barn odors or fumes, or the result of absorption from the bloodstream of the animal, which is the case with feed and weed defects.

- Bacterial. The growth of certain bacteria in the raw milk prior to processing may lead to defects such as malty and rancid flavors and odors.

- Chemical. Chemical reactions, such as oxidation, the use of certain medications near the time of milking or contact with cleaning and sanitation agents may lead to residual chemical off flavors and odors in milk.

In many cases, off odors and flavors do not dissipate with pasteurization or over time. In some cases, as with many oxidation defects, the intensity of the odor and flavor may actually increase during the shelf life of the finished product.

Assessing Raw Milk Quality by Focusing on Parameters that Influence Finished Product Quality

Methods currently used to determine raw milk quality in the dairy industry include a host of parameters such as:

- Total bacteria count (TBC), sometimes also called an aerobic plate count (APC) or standard plate count (SPC)

- Laboratory pasteurization count (LPC)

- Preliminary incubation count (PI)

- Psychrotrophic (or more appropriately, psychrotolerant) bacteria count (PBC)

- Coliform count (CC)

- Spore tests, including psychrotolerant spore count (PSC), mesophilic spore count (MSC), thermophilic spore count (TSC), or butyric acid bacteria (BAB) spore count

- Somatic cell count (SCC)

- Components, including fat, lactose, casein, and others

- Chemical factors including, fatty acids and urea nitrogen

A Three-Tiered Approach to Streamline Raw Milk Quality Testing

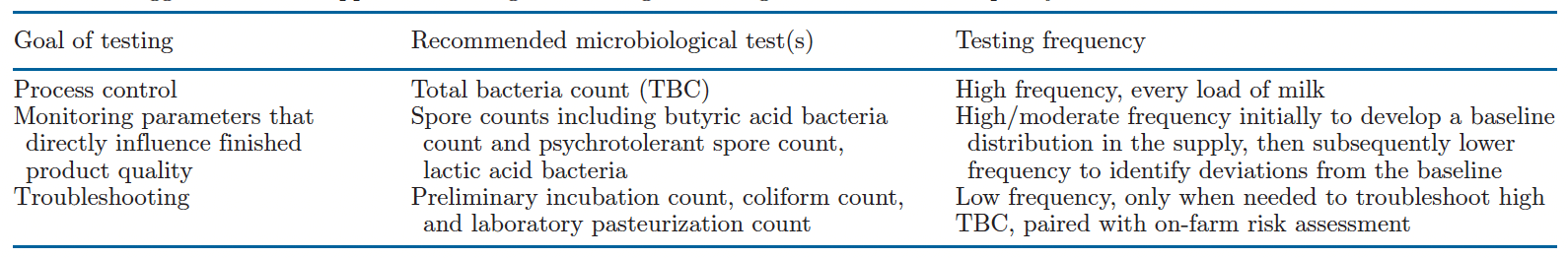

Each of these tests offers a perspective on how the raw milk was produced, handled, and stored, as well as the nutritional status, and health status of the cow at the time of milking. While these considerations are important, they don’t all directly relate to how the milk will perform in the finished product. To achieve high-quality raw milk from a finished product perspective, a three-tiered approach is recommended to streamline the use of these tests. These three tiers include:

- Process control tests – Every load of milk is evaluated for TBC as an overall microbiological marker used to indicate whether farm and management practices are adequately and consistently applied. Research indicates that when TBC is consistently kept below 5,000 cfu/mL, other microbiological and even physical parameters, including LPC, PI, PBC, CC, and SCC, are more likely to be within an acceptable range.

- Monitoring parameter tests – Moderate to high-frequency testing for parameters that directly impact the quality of the finished product being manufactured from a particular milk supply to establish a baseline, and then less frequent testing to identify when deviations from the baseline occur. These parameters may include spore tests, evaluation of free fatty acids, flavor and odor evaluation, or other parameters depending on the target finished product.

- Troubleshooting tests – The final category of tests is conducted when process control tests or monitoring parameter tests are not within the expected range. These tests, which include LPC, PI, CC, and others, should be used to support troubleshooting efforts, and must always be evaluated alongside on-farm risk assessments.

Using Raw Milk Testing to Leverage a Whole Farm Approach to Ensure Raw Milk Quality

Raw milk testing is an important component of comprehensive quality management at the farm; however, our current system is often reactive, meaning that after a milk sample is taken, we wait for results and then attempt to address issues days after the sample was originally collected. Instead, we must move forward with developing a risk-based, predictive system that allows producers to identify quality deviations before they occur. Key elements of a risk-based system are understanding the implications of farm practices on quality parameters of interest, consistent monitoring through sampling and testing practices to tackle contamination risks preemptively, and in some cases, increasing the frequency of process control testing. After all, achieving high quality raw milk that ultimately leads to high quality finished products that provide consumers with great tasting, nutritious, and innovative dairy foods is of the utmost importance to the future success of the dairy industry.

Take the Next Step Toward Predictive Quality Management

Empower your dairy operations with the tools and strategies needed to transition from reactive to proactive quality management. Explore advanced raw milk sampling systems that, along with raw milk testing solutions, help identify potential issues before they occur, ensuring high-quality milk and exceptional dairy products. Contact us today at (651) 501-2337 to learn more—because every step in the process counts toward excellence in dairy production!

Have questions about sampling for raw milk quality?

References:

Martin, N. H., Evanowski, R. H., & Wiedmann, M. (2023). Invited review: Redefining raw milk quality-evaluation of raw milk microbiological parameters to ensure high-quality processed dairy products. Journal of Dairy Science. https://doi.org/10.3168/jds.2022-22416