Biofilms in the Dairy Processing Industry—What and Why are They Important?

Biofilms in the dairy processing industry are a big problem because they threaten the quality and safety of dairy products. The growth of bacterial biofilms is the primary reason for microbial contamination of milk and other dairy products.

“In recent years, the formation and impacts of biofilms on dairy manufacturing have been studied extensively, from the effects of microbial enzymes produced during transportation of raw milk to the mechanisms of biofilm formation by thermophilic spore-forming bacteria. The dairy industry now has a better understanding of biofilms and of approaches that may be adopted to reduce the impacts that biofilms have on manufacturing efficiencies and the quality of dairy products.”

(Source: Biofilms in the Dairy Industry, Edited by Koon Hoong Teh, Steve Flint, John Brooks, and Geoff Knight)

What are biofilms in the dairy processing industry?

Biofilms are a collection of microorganisms that can grow on many types of surfaces. In the dairy processing industry, biofilms have a base of minerals, such as calcium and iron, and organic materials, such as proteins and butterfat. These deposits adhere to stainless steel dairy processing equipment and provide a haven for bacteria to attach. The attached bacteria utilize the matrix for survival and growth.

How are biofilms formed?

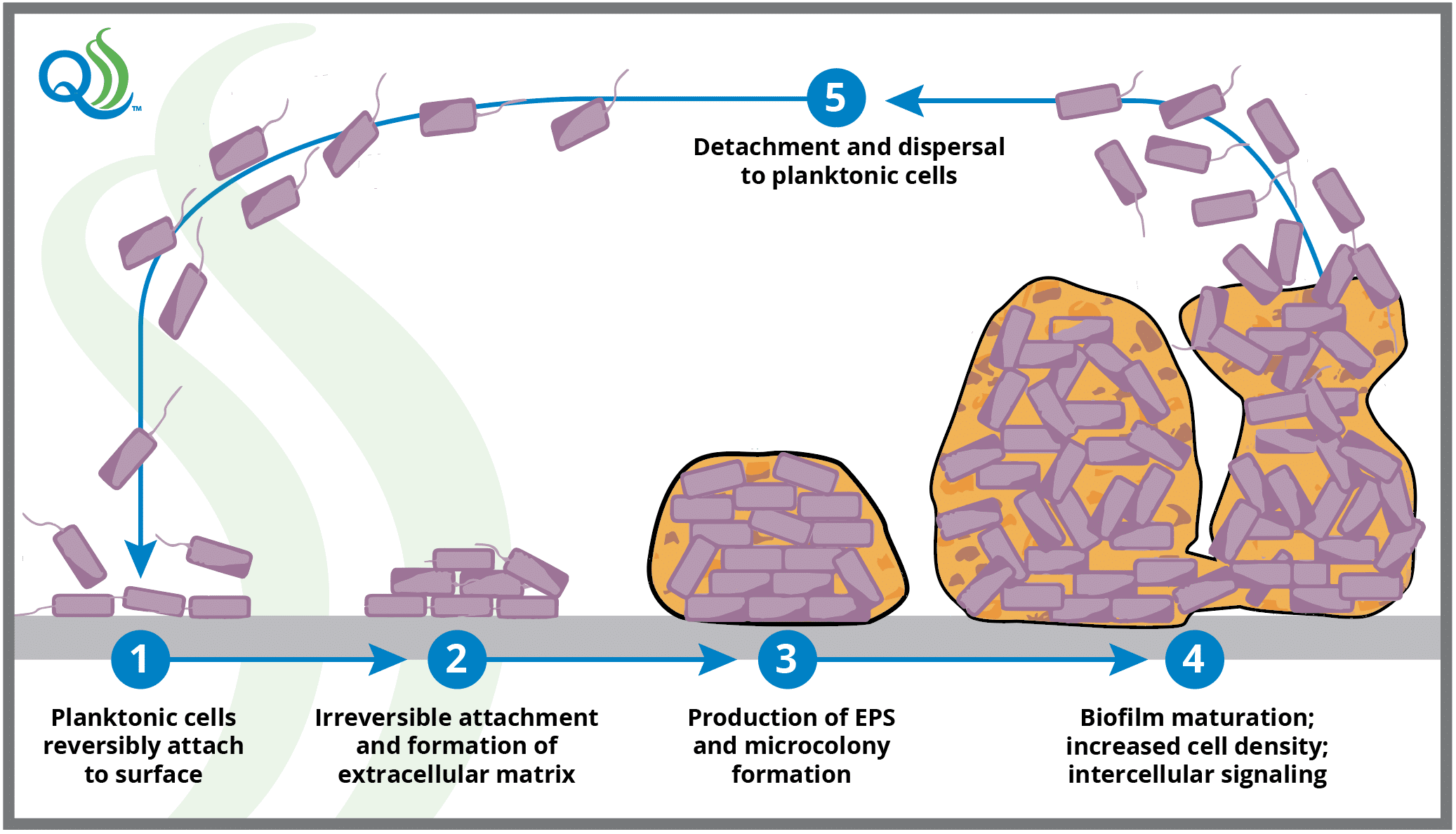

Typically, biofilms formation happens in five stages:

- Initial reversible attachment (Stage 1)

- Irreversible attachment (Stages 2 and 3)

- Maturation (Stage 4)

- Dispersion (Stage 5)

Schematic representation of a biofilm formation

The growth of biofilms on dairy processing equipment can lead to microbial contamination

Nearly all dairy handling equipment is made of stainless steel and utilizes refrigeration to keep the products cold. If biofilms are present on these surfaces, psychrotrophic bacteria, which can grow at refrigeration temperatures, will potentially end up in raw or pasteurized milk.

How pasteurization spurs the growth of spore-forming bacteria

Not all spore-formers are psychrotrophic bacteria. However, spore-forming bacteria from dairy equipment biofilms are likely to be heat-resistant psychrotrophic bacteria that are not killed by the pasteurization process. Instead, pasteurization will shock these spore-forming bacteria into outgrowth, ultimately creating quality defects in pasteurized products, especially fluid milk.

Silos are the most common contamination source for heat-resistant psychrotrophic bacteria, but other potential sources include farm bulk tanks and trucks.

“The growth of biofilms on the surface of plate heat exchanger pasteurizers can contaminate the milk with > 106 bacteria ml‐1 and this affects the quality of products manufactured from this milk.”

How to prevent the formation of biofilms

Unfortunately, regular cleaning and sanitation aren’t enough to prevent biofilm formation. Biofilms start to grow in just eight hours. As a result, regular EFFECTIVE cleaning is needed.

Microorganisms are highly protected under the residues forming the biofilm, and they will continue to grow until the overlying film is removed.

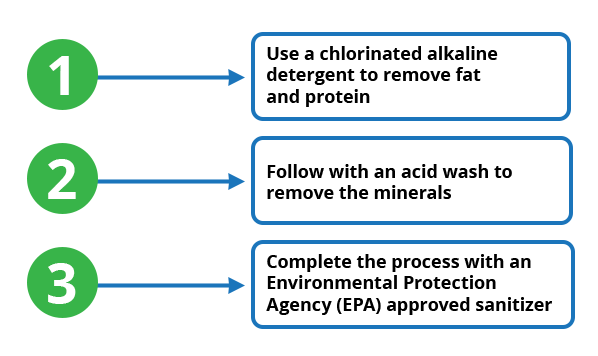

Biofilms are difficult to remove through standard cleaning and sanitizing procedures. A specific process is needed to remove biofilms effectively.

While any registered sanitizer can be used, peracid sanitizers have been shown to be the most effective in biofilm penetration. Keep in mind that unless the biofilm is completely removed, complete elimination of the spoilage organisms will not be successful.

The presence of potential biofilms in dairy processing equipment can be identified through effective aseptic and representative sampling, followed by standard plate counts and lab pasteurized counts.

Controlling the presence of biofilm is dependent mainly on the effectiveness of clean‐in‐place systems like those from QualiTru. Diligence in the prevention and removal of biofilms is essential to producing high-quality dairy products.

Have questions about aseptic and representative sampling? Ask Our Experts