Aseptic Sampling System: Why Consistent Test Results are Important

An aseptic sampling system is critical for the quality control process in the liquid food industry. One of QualiTru’s customers in the yeast-fermented beverage business (Brewery) had a specific problem they were facing.

Customer problem: Inconsistent results from quality samples

Of course, our team took on the challenge of solving the vexing problem of inconsistent test results from aseptic sampling. Why?

Providing our customers with equipment and services for accurate and representative sampling is our company’s mission, and it drives our passion for helping customers meet their quality and business goals.

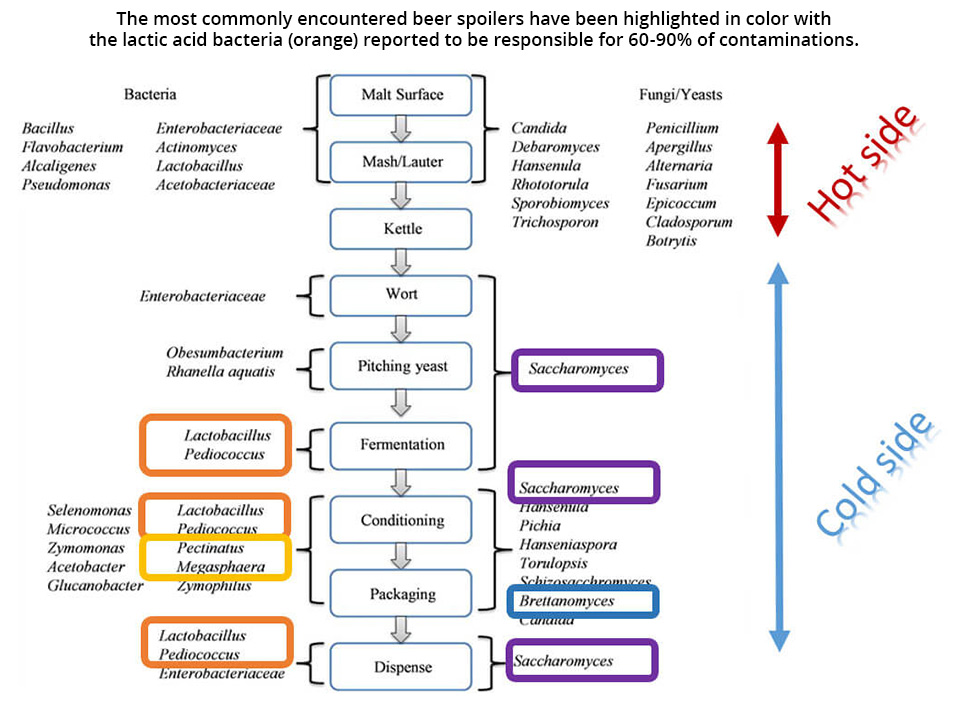

Inconsistent sampling results when testing for bacterial contamination

The customer’s high-sugar content fermentable product is good for both yeast and bacteria, but it’s not a good combination if you are making a high-quality drink.

(Image courtesy of BIOMÉRIEUX )

As part of their quality check process, the brewery routinely sampled and cultured the final clean-in-place (CIP) rinse water to ensure no bacterial contamination remained in the system.

However, the test results recorded were inconsistent and looked like random noise—some results showed high levels of bacteria while others showed low levels.

The existing aseptic sampling system raised more questions

Regular quality checks were necessary to make critical business and operational decisions. Here’s the problem though, how can you make good decisions if you get sampling results that are inconsistent, essentially random noise?

Because of this problem, some questions needed to be answered first. Do you…

- …spend the time and money to run another cleaning cycle?

- …spend the time and money to tear the system down to isolate the contamination—not knowing if it even exists?

- …take your chances and run the next batch of the product?

Identifying the source of inconsistent test results

The QualiTru team sampling experts took the time to evaluate the current quality and sampling process. We discovered the problem was all too common and a typical one— the sanitary valve to capture a final CIP rinse water sample. Their existing process told them about the valve and the container, but not about their system.

There were really two problems:

- The valve used was not aseptic

- The collection container was not sterilized

Aseptic and representative sampling solution for consistent test results

We proposed a solution that produced an aseptic and representative sample of the final CIP rinse water. As a result of implementing our solution, the previous method’s random noise (spikes) was replaced with data that showed very few spikes.

With the new process in place, an elevated test result was a positive indication that some level of contamination still existed in the system. The customer now had more reliable data and precise indications than just random noise.

Our aseptic and representative sampling solution for their application included the following products:

Accurate sampling data = Informed business decisions

The management could now make better and more informed decisions using accurate data from the consistent test results. These decisions included no longer having to run unnecessary CIP cycles, tearing down parts of the system to search for something that wasn’t there, or taking chances on the quality of their final product.

We are proud to not only have an impact on their bottom line by saving them time and money, but we also helped to protect their brand reputation.

As we like to say around here, “Your Test Result is Only as Accurate as Your Sample.”

Have questions about aseptic and representative sampling? Ask Our Experts