String Sampling RE-Imagined for Milk Quality and Much More…

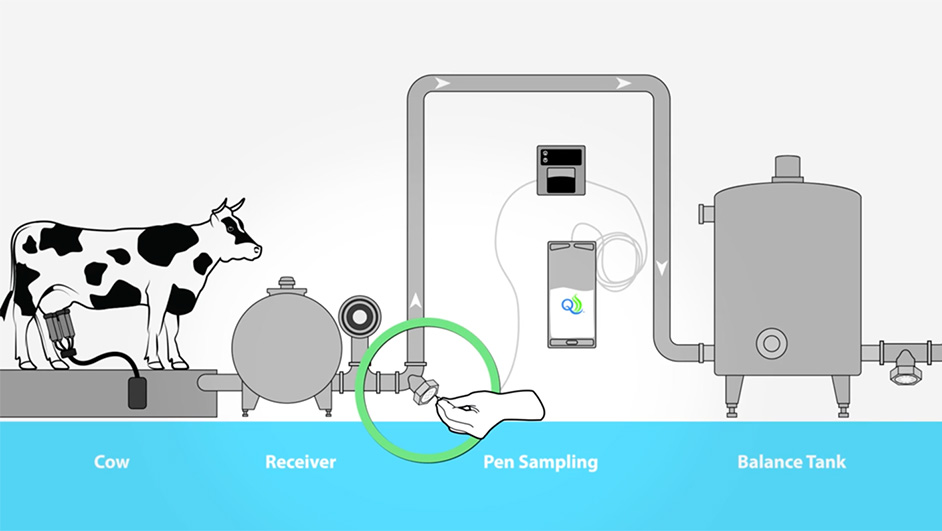

String sampling has traditionally been an affordable and reliable method for monitoring milk quality and udder health on commercial dairy farms. While that application is the most widely used, string sampling offers much more.

Do you want to improve efficiency and better manage costs? Other farm applications can benefit significantly by adapting QualiTru’s string sampling system. Here are QualiTru’s innovative and effective RE-Imagined string sampling applications.

You have sampling challenges; we have reliable solutions

Dairy farmers face two major challenges. They are:

- Mastitis management in dairy cows

- Improving herd health

Fortunately, both problems are addressed effectively with string sampling. String sampling using the QualiTru system is a proactive measure to help prevent costly mastitis by regularly gathering data to monitor trends. This allows the dairy manager to act quickly to identify a pen with a high somatic cell count (SCC). In addition, string sampling reduces the samples needed for testing compared to individual cow testing. Studies show that lowering SCC also leads to increased profits.

According to the research study, Reducing Somatic Cell Count in Dairy Cattle published by Michael Looper, Professor and Department Head – Animal Science at the University of Arkansas, “The primary reason for dairy producers to reduce SCC is because SCC relates to milk losses due to mastitis.”

RE-Imagine Sampling: Bovine Viral Diarrhea (BVD) Management

BVD management requires a comprehensive program of vaccinations and monitoring. The disease typically spreads through contact with other recently infected or Persistently Infected (PI) animals shedding the virus. While a strong vaccination program will minimize transmission and allow containment of the virus, no vaccine is 100% effective. Therefore, continual exposure to the virus from one or more PI carriers may cause infection in vaccinated animals.

To identify acutely infectious cows or PI carriers within a herd, a test protocol to detect the BVD virus using milk from bulk tanks or string sampling is a cost-effective method for monitoring the health of your herd.

RE-Imagine Sampling: Nutrition

Using string sampling to manage feed rations and analyze pen performance gives you the power to fine-tune rations. Fatty acids such as de novo and preformed fatty acids give insight into rumen health and performance. Their levels directly impact animal health and are the building blocks for milkfat, a key factor in determining payment.

Typically, fatty acid testing is done on individual cow samples or bulk tank samples. However, string sampling for fatty acids allows veterinarians and nutritionists to sample more often and target specific pens of cows where the monitoring of rumen health is of greater importance.

The QualiTru system for string sampling is cost-effective for monitoring milk quality and udder health in dairy herds. By RE-Imagining string sampling, we believe there are additional sampling applications that can increase your efficiency and profits.

We encourage you to lower your SCC and have conversations with your veterinarian and nutritionist regarding BVD monitoring and nutrition. Then, you can partner with QualiTru! With almost 40 years of expertise in the dairy industry, we can provide solutions for your sampling challenges.

Here are additional resources on our website that will help you learn more about string sampling.

- Sampling for Mastitis Detection Case Study

- Field Validation Study

- Printable Application Site Schematics

- Sampling Solutions Infographic

- Training Videos

Have questions about string or aseptic and representative liquid sampling? Ask our experts for a free consultation or call us at 651-501-2337. We love troubleshooting issues and using analytics to solve complex problems to provide customer-focused insight.