Using a Peristaltic Pump for Representative Sampling—FAQs

A peristaltic pump is commonly used to collect a representative milk sample by farmers and veterinarians. There are several reasons to use QualiTru’s sampling system for collecting representative composite samples of milk. These include:

- Milk quality and bonus payments (Representative Sampling (Direct Load))

- Identifying and isolating contamination within the milking process (Inline Sampling)

- Herd health management (String (Pen) Sampling)

- Regulatory purposes (Regulatory Approvals)

In this post, I’ll go over some of our new customers’ frequently asked questions (FAQs) about using a peristaltic pump for representative sampling.

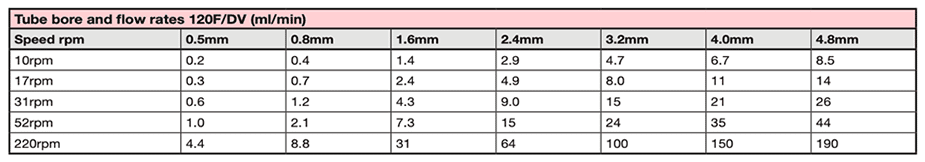

How many milliliters (ml) of milk are pulled each time the pump rotates?

We use a Watson Marlow 120S pump with a 114DV pump head. The chart below from Watson Marlow is handy when determining how many milliliters of milk are pulled per rotation.

The collection bags have a 3.2-millimeter (mm) tubing attached. Taking the numbers in the 3.2mm column and dividing by the numbers in the Speed Revolutions Per Minute (RPM) column on the far left gives you the number of milliliters (ml) pulled with each pump head rotation. It works out to 0.45 ml to 0.48 ml per rotation, when you do the math.

You can find more valuable tips in our Watson Marlow Peristaltic Pump User Guide.

Does the sampling device detect when the milk pump is running?

The answer is no, assuming the customer is referencing the milk transfer pump, not the vacuum pump. The peristaltic pump is turned on manually at the beginning of the sampling process and turned off manually once the sampling process is complete, which is typically when the trailer and collection bags are full, or for pen sampling when the sampling duration is complete. So the peristaltic pump will continue to run at a constant rate even if there is a period of downtime with no milk flowing through the pipe.

Is the sampler pump rate set based on the hours it takes to complete milking or the volume of the tanker/bulk tank?

The RPM of the peristaltic pump is set based on the time it takes to fill the tanker/bulk tank. Our collection bags hold two liters or 2,000 ml. We recommend a sample size of no more than 1,500 ml to ensure there is space left in the bag to allow for proper agitation before sample removal. 1,500 ml is the preferred amount, but there may be instances when there are only 1,200 ml in the bag. It is not an exact science.

To calculate the pump’s RPM, we use the following formula (which can be found in the Watson Marlow Peristaltic Pump User Guide).

(1,500 ml collection bag) / (Run time in minutes to fill the tanker) x 2 =

Watson Marlow RPM Setting.

If it takes four hours to fill a tanker/bulk tank, the formula will look like this:

(1,500 ml collection bag) / (240 minutes) x 2 = RPM setting of 13.

Let’s say you have a dairy farm that takes 24 hours to fill a tanker/bulk tank. During this process, they have three milking shifts of six hours each, so essentially, it takes 18 hours of actual milking time to fill the tanker/bulk tank. So the formula will look like this:

(1,500 ml collection bag) / (1,080 minutes of milking time to fill the tanker/bulk tank) x 2

= RPM setting of 3.

In the previous example, the employees will remove the needle from the septum and the tube from the peristaltic pump. They will put the tube in the refrigerator to keep it cold until the next milking shift. When they are ready to start the next milking shift, they will set the system up to sample again. They will repeat this process until the tanker/bulk tank is full. The collection bag will then be a representative sample across all the milking shifts.

Refer to our handy Peristaltic Pump Setting Infographic.

Where should the port be installed to get a representative sample?

The port should be installed on the cold side of the plate cooler and as close to the trailer/bulk tank as possible, ideally in a place where there is a constant/consistent flow of milk.

What else is important to know about the peristaltic pump setup to ensure that the sample is representative?

The tubing must be in the pump, and the clamshell closed before inserting the needle into an unused septum channel. If we insert the needle first, the pressure in the system will rapidly fill the bag. Therefore, the end result is not representative if a cup of milk enters the collection bag two seconds into the sampling period.

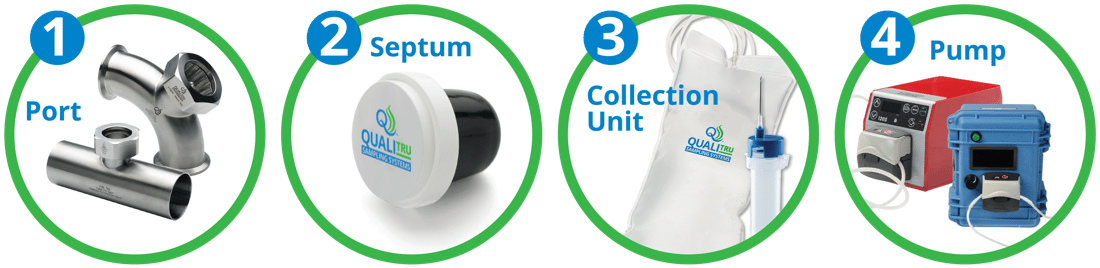

Our sampling system is as easy as 1-2-3-4

The 4-part QualiTru system, consisting of a stainless steel port, septum, and a sterile collection bag, paired with a peristaltic pump for added control, provides the necessary components for accurate and representative sampling for end-to-end process control. When a system and peristaltic pump are ordered, you receive application and sampler settings documentation to support sampler installation.

Our sampling experts can also assist in providing the specific information you need for confidence in your installation and sampling protocols.

Check out our library of training materials and videos on our website for additional support. We know customers may still have questions, so we ask, “How can we help?”

QualiTru is committed to providing sampling expertise through training and support materials on our website. They are presented in a variety of formats, including our standard operating procedures (SOPs), case studies, blogs by subject matter experts (SMEs), training videos, infographics, and schematics. In addition, when you order a sampling system and peristaltic pump from QualiTru, you receive application and sampler settings documentation to support sampler installation.