Water System Testing for Microorganisms in a Brewery – Committed to Quality

Water system testing for microorganisms in a brewery is a regular part of the process at Cold Spring Brewing Company (CSBC). It has been the hallmark of this iconic brewery for well over a century and shows its total commitment to quality.

A brief history of CSBC

CSBC is located in Cold Spring, Minnesota. It has a long history of tradition and quality dating back to 1874 when Michael Sargl, a German immigrant, started brewing beer on site. As one of Minnesota’s first breweries, it weathered Prohibition through diversification, as well as the ups and downs of the macro brewing industry over the years. Its ability to adapt and innovate has continued to move the company forward and grow, employing 600 people.

In 2012, CSBC launched its craft beer division called the Third Street Brewhouse. Today, more than a dozen year-round, seasonal, and specialty varieties of craft beer are available in liquor stores and on tap in many bars and restaurants.

As part of the brewery’s growth, CSBC acquired Carolina Beverage Group LLC in 2018, becoming one of the largest independently-owned contract manufacturers in the beverage sector. They produce, package, and distribute to top names in soft drinks, beer, malt beverages, sparkling waters, organic energy drinks, teas, specialty drinks, and more. CSBC produced 65 million cases of product on five production lines in 2020.

“The brewing industry has grown exponentially over the past decade, with new entrants crowding the market. Today more than ever, due to the variety of beer styles and brewing complexity, quality management has become a critical differentiator. The need for accurate, actionable information during production and post-packaging is essential to maintain quality and protect brand image.” (Source: Invisible Sentinel, A bioMérieux company)

Microbiological stability in the brewing process

Brewery contaminants are microorganisms that cause spoilage in brewery products. One of the significant challenges that breweries face is the production and maintenance of beer quality. Breweries and good water have long had a close association, and water quality is generally taken for granted.

The microbiological stability of the final product can be compromised from a very early point in its production, with spoilage organisms able to access the brewing process at every stage. Most potential contaminants of beer originate from raw materials and/or unclean brewing equipment. Brewing raw materials, such as malt, hops, and brewing water could be infected by microorganisms. (Source: Brewery Contaminants, Challenges and Remedies-A Review).

“According to a study published in a 2003 issue of the International Journal of Food Microbiology, the “most hazardous [bacteria] for the brewing industry are those belonging to the genera Lactobacillus and Pediococcus. In the period 1980 to 1990, 58 to 88 percent of the microbial beer-spoilage incidents in Germany were caused by lactobacilli and pediococci.” (Source: Ecological Society of America (ESA)).

Why is accurate water system testing so critical to meeting the brewery’s high standards?

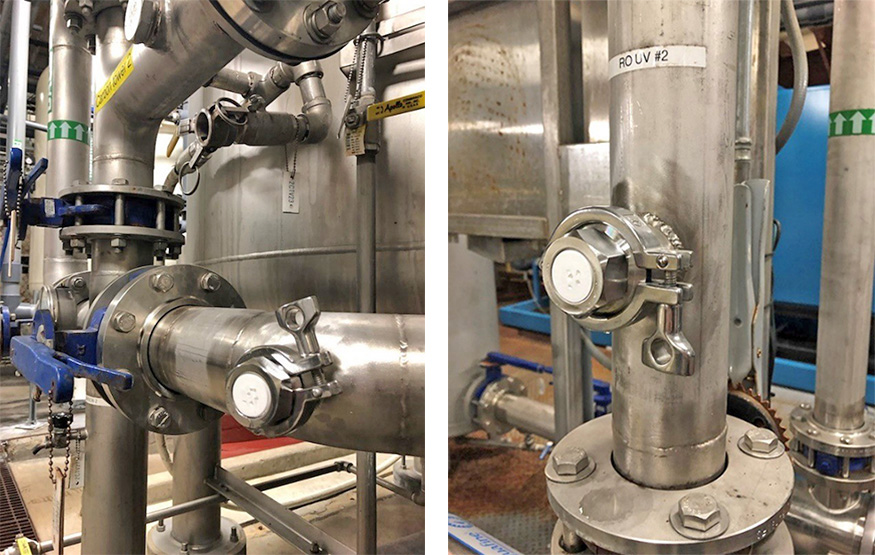

For more than a decade, CSBC has utilized the QualiTru Sampling System to identify microorganisms in its water system. They currently have 18 QualiTru sampling port locations throughout their plant in Minnesota and rely heavily on the QualiTru system for accurate samples. Reverse osmosis (RO) and ultra-violet light treatment systems, along with the QualiTru system, have been critical elements of their quality control procedures.

One of CSBC’s main strengths is its ability to run multiple products at the same time. With new trends such as hard-seltzer products hitting the market in high demand, CSBC has a minimum of two production lines running hard-seltzer products throughout the day, every day. This process allows them to produce high-quality products for their customers.

“Producing product at the highest standard possible is our goal here at CSBC. QualiTru sampling systems help us make sure we are meeting that goal with accurate water tests and uncompromised water samples,” says Mat Eischens, Process Control Supervisor at CSBC, since 2006.

QualiTru is the reliable aseptic access solution for the leaders in the diary, brewery, and beverage and liquid products industry.