Post-Pasteurization Contamination Monitoring: A Canary in the Coal Mine

Post-pasteurization contamination in dairy plants is a warning signal for potential food safety and spoilage concerns. While having an effective sanitation program gets the most attention, good sanitation alone cannot guarantee product quality and food safety. Sampling and testing products during processing are critical for identifying potential sources of post-pasteurization contamination.

Possible causes of post-pasteurization contamination

Engineering defects such as cracks and pinholes in high-temperature short-time (HTST) pasteurizer plates, cracks in storage tanks or tank doors, and contaminated compressed air are possible sources of post-pasteurization contamination that are often overlooked. Tiny access points to the process can cause serious quality and shelf stability problems. In addition, these defects could harbor both spoilage and pathogenic organisms.

Effective process monitoring is more than just total bacterial counts

Total bacterial counts are not the most effective method for detecting post-pasteurization contamination. Effective process monitoring must focus on the type rather than the number of bacteria.

Monitoring Microbial Contamination

FREE on-demand webinar presented by Darrell Bigalke, Founder and Owner

Since gram-negative bacteria generally do not survive pasteurization, their presence in pasteurized products indicates process contamination. The contamination level of gram-negative bacteria in pasteurized dairy products may be extremely low, often < 1 bacterium per gallon.

Many gram-negative bacteria can grow rapidly at refrigerator temperatures. However, the presence of even very small numbers of these ‘psychrotrophic’ bacteria may result in premature spoilage. More importantly, gram-negative bacteria could also indicate foodborne pathogens, such as Salmonella, E. coli, or Cronobacter. See my earlier post, Heat-Resistant Psychrotrophic Bacteria and Their Effect on the Quality of Pasteurized Milk.

Understanding the generation time of gram-negative psychrotrophic bacterial populations

Even very small numbers of gram-negative bacteria in finished products can be significant because of their growth rate (also called doubling rate or generation time).

In pasteurized dairy products, the growth rate depends on the type of organism, availability of oxygen, storage temperature, and access to nutrients. Milk is a very nutrient-rich medium for bacterial growth. Psychrotrophs grow faster as temperatures warm, peaking at about room temperature.

The graph below demonstrates the significance of the generation time of gram-negative psychrotrophic bacterial populations on milk spoilage, starting with one organism per gallon.

| Doubling Rate (hours) | Approx. Storage Temp ˚F (˚C) | Days to Spoil* |

|---|---|---|

| 7 | 45˚ (7.2˚) | 10 |

| 12 | 41˚ (5˚) | 18 |

| 18 | 39˚ (4˚) | 26 |

Read How Bacterial Generation Times Impact Fluid Milk Quality and Shelf-life to learn more about this critical topic.

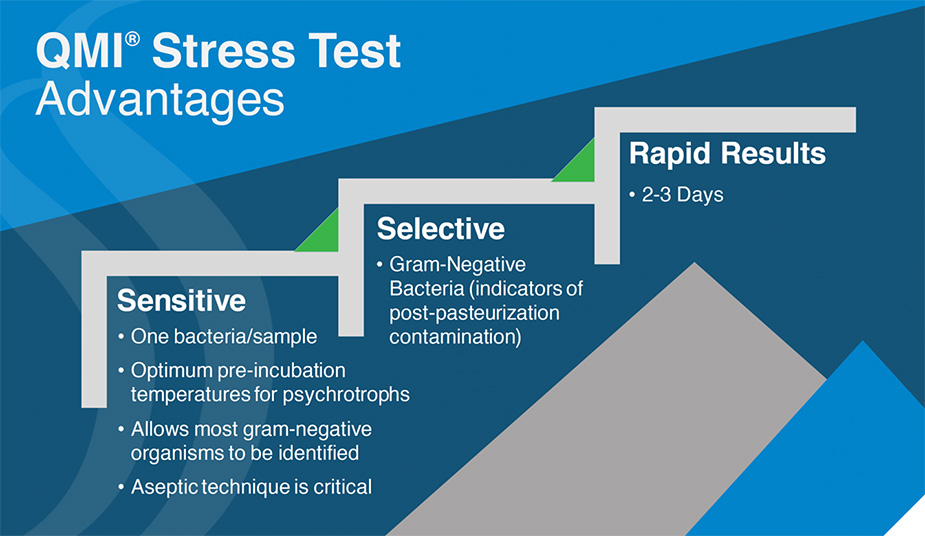

QMI Stress Test – Proactively monitoring post-pasteurization contamination

The patented QMI Stress Test is a proven effective and efficient method to monitor post-pasteurization contamination proactively.

For this test, a two- to five-liter milk sample is aseptically collected immediately after the HTST, out of each storage tank, and from an elbow just before the filler. The sample size is critical because very low levels of gram-negative bacteria will only be detected in such a large sample.

The use of an oxygen-permeable sterile collection bag for sample collection is vital as gram-negative bacteria need oxygen for optimum growth. Once collected, the samples should be incubated at room temperature for 48 hours and then plated on Violet Red Bile Agar (VRB) or sodium deoxycholate to select for gram-negatives. If gram-negative bacteria are detected, the test is positive for post-pasteurization contamination, suggesting the need for further investigation and corrective action.

To summarize, since gram-negative bacteria do not survive pasteurization, detecting their presence in process monitoring samples is a warning sign of post-pasteurization contamination that can lead to spoilage and food safety issues.

The QMI Stress Test is a proactive procedure to uncover sources of very low contamination loads that could blow up into more serious problems. On this website, you’ll find more information on sterile post-pasteurization line sampling for dairy plants, to detect and identify sources of contamination that impact milk quality.

Don’t take chances. Sample proactively and often to ensure that your process is not contaminating your product.

Have questions about aseptic and representative sampling for dairy plants?