Understanding Bacterial Generation Times and Their Impact on Milk Quality

Bacterial generation times—the average time it takes for bacteria to double in population—have a significant impact on the quality of fluid milk and its shelf life, regardless of the source of microbial contamination. While many factors can lower the quality of fluid milk and reduce shelf life, the most significant is microbial spoilage, making it essential to monitor and control bacterial growth effectively.

Left unchecked, microbial growth can lead to spoilage, off-flavors, and reduced consumer trust. By understanding the science behind bacterial reproduction and implementing proactive quality control strategies, dairy plants can protect product integrity and extend shelf life.

Generation time is the time it takes a bacterial population to double under specific storage conditions.

“As the ability to kill, remove, or control microbial growth in pasteurized refrigerated milk continues to improve, the original milk Somatic Cell Count (SCC) will be the factor limiting the time of refrigerated storage before development of an off-flavor in milk.”

(Source: Influence of raw milk quality on fluid milk shelf life, D M Barbano, Y Ma, M V Santos, National Library of Medicine).

How Bacteria Multiply: The Science of Binary Fission

Regardless of the source of the contamination, the amount is not the primary concern. It is the growth rates of specific bacteria that most significantly impact pasteurized milk quality and shelf life.

Bacteria reproduce through a process known as binary fission; one bacterium duplicates its genetic material and becomes two bacteria —driving population growth when conditions are favorable. This rapid reproduction enables bacteria to thrive under favorable conditions, such as warm temperatures and nutrient-rich environments. The time it takes for bacteria to double—known as the generation time—varies depending on factors like:

- Temperature: Psychrotrophic bacteria grow even at refrigeration temperatures.

- Nutrient Availability: Milk’s nutrient composition makes it particularly susceptible to microbial growth.

A simple growth model (e.g., N(t) = N₀ × 2^(t/g)) helps processors estimate how quickly low counts reach action limits and align sampling, hold times, and sanitation to real microbial behavior. Understanding these dynamics is crucial for identifying contamination risk and protecting pasteurized milk quality.

The Link Between Bacterial Growth Rates and Milk Shelf Life

The Pasteurized Milk Ordinance (PMO) limits the total bacterial count for Grade-A pasteurized milk to 20,000 per milliliter. However, the total bacterial count is not the whole story.

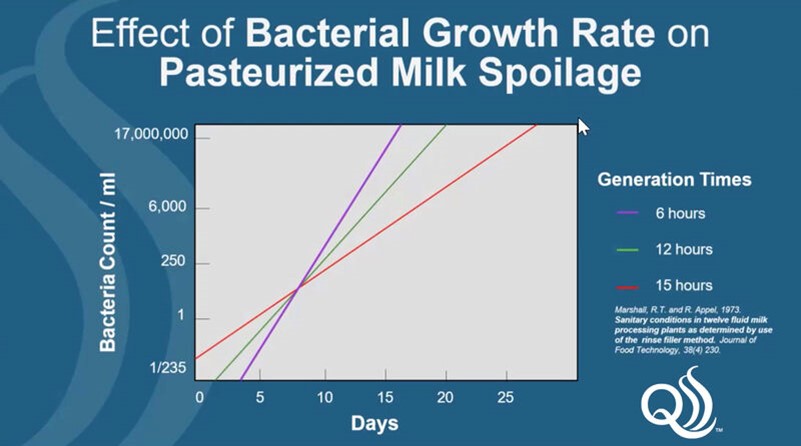

This chart illustrates how the variability of generation time impacts milk spoilage for three different types of bacteria. Using this example of milk containing bacteria:

- The longest generation time of 15 hours has a shelf life of 25 days.

- A 12-hour generation time shortens the shelf life of milk to 15 days.

- The shortest generation time of six hours reduces the milk’s shelf life to twelve days.

In this illustration, the bacteria were all at the same population level (1 bacterium capable of growth at refrigeration temperatures per milliliter) on Day 5. However, the different bacterial growth rates resulted in significant variability in shelf life.

By monitoring bacterial growth rates, dairy plants can better predict spoilage timelines and take corrective actions to help ensure product quality.

“Effective strategies for extending fluid milk product shelf life by controlling bacterial growth are of economic interest to the dairy industry.”

(Source: Evaluation and Improvement of Raw and Pasteurized Fluid Milk Quality, Nicole Martin, Cornell University).

How Psychrotrophic Bacteria Threaten Pasteurized Milk Quality

Heat-resistant Psychrotrophic Bacteria or Heat-Resistant Psychrotrophs (HRP) are defined as those that grow at refrigeration temperatures and are the most detrimental to milk quality. Their presence in fluid milk will result in quality defects.

These bacteria originate from cold environments. While they generally have very low contamination levels initially, they significantly impact spoilage due to their fast-generation times at refrigeration temperatures, leading to:

- Off-flavors and unpleasant odors.

- Shortened shelf life.

- Consumer dissatisfaction.

Strategies for Monitoring and Controlling Microbial Spoilage of Fluid Milk

It is critical to implement continuous process monitoring to quantify bacteria and identify bacterial types. Because their incidence is generally very low, identifying psychrotrophic bacteria in fluid milk requires large volumes of aseptic and representative samples.

Gram-negative psychrotrophic bacteria are highly dependent on oxygen for optimum growth; the use of oxygen-permeable incubation containers is a necessary identification component. Confirmation of the bacteria type should be made through a gram stain. To learn more, watch our free on-demand webinar, Monitoring Microbial Contamination.

Learn More About Controlling Microbial Spoilage

Understanding and managing microbial spoilage are key to maintaining milk quality and extending shelf life. Dive deeper into strategies for combating spoilage by visiting our blog: Combat Microbial Spoilage in Dairy Processing.

Free Resource: Complete the form below to download our Microbial Spoilage Chart to identify and control common spoilage risks effectively. This resource provides actionable insights to help you enhance your dairy processing operations.

Protect Your Milk Quality with Reliable Aseptic Sampling

Maintain precision in monitoring bacterial activity to safeguard the quality and safety of your dairy products. Contact QualiTru today to learn more about our aseptic and representative sampling systems and microbial testing solutions.

QualiTru’s representative sampling system is approved for use by the Pasteurized Milk Ordinance (PMO). See Regulatory Approvals.

Have questions about aseptic and representative sampling? Ask Our Experts