Combat Microbial Spoilage: Ensuring Dairy Quality Assurance with QualiTru

The dairy industry faces the continuous challenge of maintaining the safety and quality of milk and its derivatives. Despite significant advancements in processing technologies, a 2018 paper in the Journal of Dairy Science reported that nearly half of all fluid milk products show evidence of post-pasteurization contamination with psychrotrophic or psychrotolerant spoilage organisms.1 This contamination primarily stems from Gram-negative rods, especially Pseudomonas spp., which are adept at flourishing at refrigeration temperatures, thereby causing microbial spoilage and jeopardizing product integrity.

The Imperative of Pasteurization

Pasteurization is a crucial barrier against pathogenic organisms in milk. However, it doesn’t wholly eradicate spoilage organisms. Some of these, such as spore-forming and thermoduric lactic acid bacteria, can survive the process. This underscores the need for vigilant monitoring and control measures beyond pasteurization to ensure dairy product safety.

Tackling Post-Pasteurization Contamination

The journey from cow to consumer poses multiple opportunities for milk contamination. At the farm level, inadequate cleaning of the udder, use of contaminated milking equipment, and improper milk storage conditions can introduce spoilage organisms. During transport and within processing facilities, the failure to maintain optimum temperature controls and equipment sanitation failures further compound the risk of contamination.

Read more about Post-Pasteurization Contamination Monitoring.

Microbial Spoilage and Its Impact

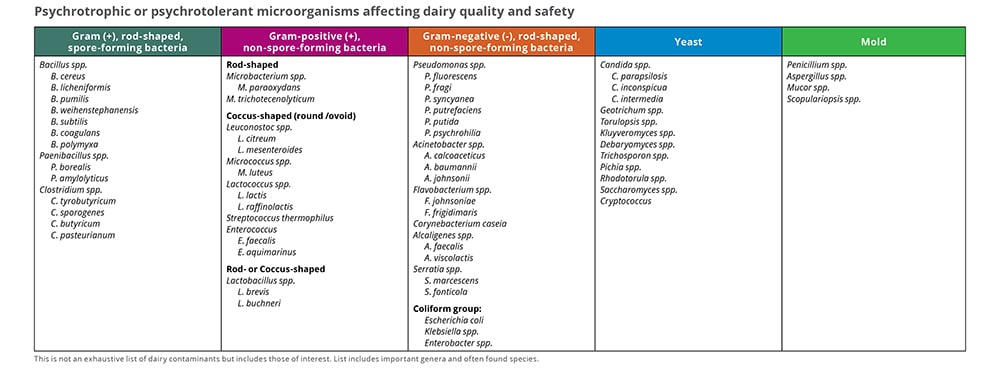

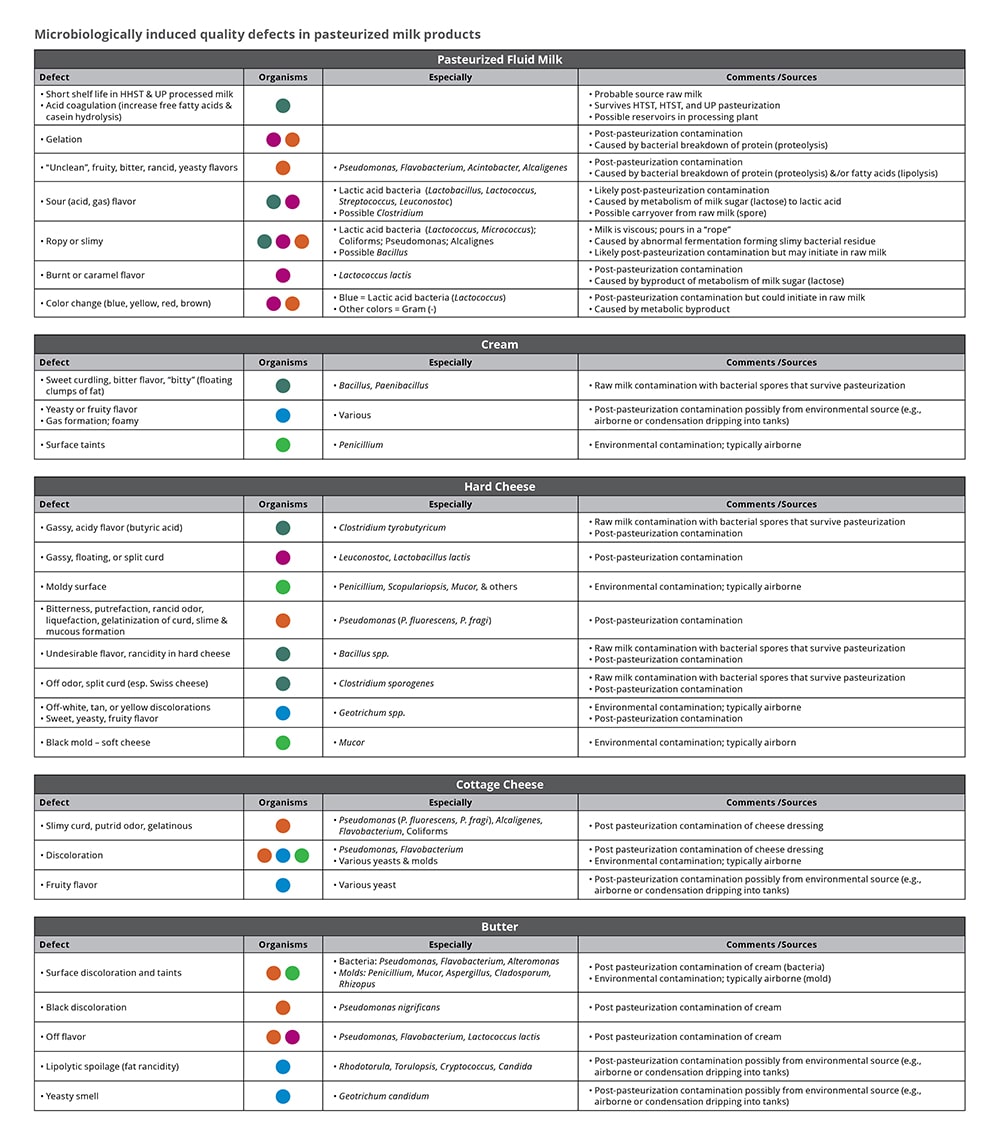

The following charts highlight the diverse microbiological agents, including bacteria, yeasts, and molds, that can spoil dairy products. These organisms can induce a range of spoilage phenomena, from off-flavors and odors to physical changes in texture and color. Understanding the specific microbes responsible for spoilage is crucial for implementing targeted quality control measures.

FREE Laminated Dairy Micro 101: Spoilage of Milk & Milk Products

Complete the form below to receive a FREE laminated copy of our popular ‘Dairy Micro 101: Spoilage of Milk & Milk Products Guide,’ which includes the reference charts above!

The Economic and Safety Imperatives of Quality Assurance

Adopting advanced quality assurance measures, such as those enabled by QualiTru sampling systems, is a matter of safety and economic prudence. By preventing spoilage and extending product shelf life, dairy processors can minimize waste, avoid costly recalls, and protect their brand reputation. This proactive approach to quality assurance represents a strategic investment in the long-term viability and success of dairy operations.

Read more about the Economics of Quality Assurance in Dairy Processing.

QualiTru Sampling Systems: A Cornerstone in Dairy Quality Assurance

The journey towards exceptional dairy product quality begins at the farm and continues throughout the processing chain. QualiTru’s aseptic sampling systems deliver a reliable and efficient means for dairy quality assurance professionals to detect and manage post-pasteurization contaminants. By facilitating accurate, timely, and reliable sampling, QualiTru systems enable proactive interventions, helping to maintain the highest standards of dairy product safety and quality.

For over four decades, the dairy industry has trusted QualiTru Sampling Systems for rapid, straightforward, secure, and precise sampling for bacterial and chemical analysis. With the cost-effectiveness of each sample, QualiTru’s sampling solutions, including the innovative TruStream™ Septa and TruStream Ports, are extensively utilized on farms and in dairy processing. This widespread use underscores the value of QualiTru’s systems in providing the comprehensive and consistent quality assurance necessary in today’s dynamic dairy processing landscape.

Have questions? Contact us to unleash the power of process monitoring.

[1] Martin NH, KJ Boor, M Wiedmann. Symposium review: Effect of post-pasteurization contamination on fluid milk quality. J Dairy Sci, 2018; 101:861-870.