Cheese Quality Control Through Aseptic Sampling

Controlling bacteria and spores in cheese plants is a critical aspect of cheese quality control. The challenges associated with bacterial and bacterial spore contamination that lead to spoilage or quality control defects in cheese production are multifaceted and require a comprehensive understanding of the microbiological factors involved. Cheese quality control issues caused by harmful bacteria can cause various defects, including off-flavors, gas production, and textural irregularities.

Aseptic sampling is crucial for cheese quality control, helping producers maintain product integrity from production to consumption. QualiTru sampling systems offer reliable and effective aseptic sampling solutions, helping achieve the highest standards in cheese production.

Microbial Quality Control in Cheese Plants

To ensure the quality and safety of cheese products and to address specific bacterial concerns, such as the spore former Clostridium spp. that is responsible for late-blowing defects, it is essential to monitor raw and pasteurized milk’s microbiological quality, as well as the production environment. Cheesemakers conduct microbiological tests on raw and pasteurized milk to assess the microbial load and detect the presence of pathogens and spoilage microorganisms. These tests include:

- Total Plate Count (TPC)

- Coliform Count

- Somatic Cell Count (SCC)

- Laboratory Pasteurization Counts (LPC)

- Yeast and Mold Count

- Specific Pathogen Testing: This includes testing for Listeria monocytogenes and Escherichia coli, which are pathogens of particular concern for cheesemakers.

The results of these tests guide decisions regarding the acceptance or rejection of milk for cheese production.

Spoilage Microorganisms Affecting Cheese Quality Control

Microorganisms that cause cheese spoilage include a range of bacteria, yeasts, and molds. These spoilage agents can lead to undesirable changes in flavor, texture, and appearance. Common spoilage microorganisms in cheese production are:

- Lactic acid bacteria: Beneficial in controlled amounts but can cause spoilage if overgrown.

- Yeasts and molds: This can introduce off-flavors and spoilage in the final product.

Harmful Bacteria in Cheese

Harmful bacteria can pose significant health risks when present in cheese. Some of the most concerning bacteria include:

- E. coli / Coliform bacteria in cheese: Indicators of fecal contamination, which can lead to serious foodborne illnesses.

- Listeria in cheese: Capable of surviving and growing at refrigeration temperatures, making it a persistent threat.

- Salmonella in cheese: Often introduced through contaminated raw milk or poor hygiene practices.

Historical Context of Cheese Quality Control

Many cheeses represent greater pathogenic risk than fluid milk. For example, from 1998 to 2011, 90 foodborne illness outbreaks involving 1,882 people were caused by contaminated cheese. There were six deaths associated with these outbreaks. Of 82 outbreaks where the pasteurization status of the milk was reported, 44 (54%) were from pasteurized milk. The most common pathogens isolated from these outbreaks were Salmonella spp. and Listeria monocytogenes. (Source: Foodborne Pathogens and Disease Vol. 11, No. 7)

Implementing a HACCP Plan for Cheese

A Hazard Analysis and Critical Control Points (HACCP) plan is essential in cheese production to identify and control potential hazards. Key steps in a HACCP plan include:

- Conducting a hazard analysis: Identify potential biological, chemical, and physical hazards.

- Determining critical control points (CCPs): Points in the process where controls can be applied to prevent or eliminate hazards.

- Establishing critical limits: Maximum or minimum values to which biological, chemical, or physical parameters must be controlled.

- Monitoring CCPs: Regularly check and record data to ensure critical limits are met.

- Implementing corrective actions: Steps to be taken when monitoring indicates that a CCP is not under control.

- Verifying procedures: Validate that the HACCP system is working effectively.

- Record-keeping: Maintain documentation and records to demonstrate HACCP compliance.

Sample Collection for Microbiological Testing

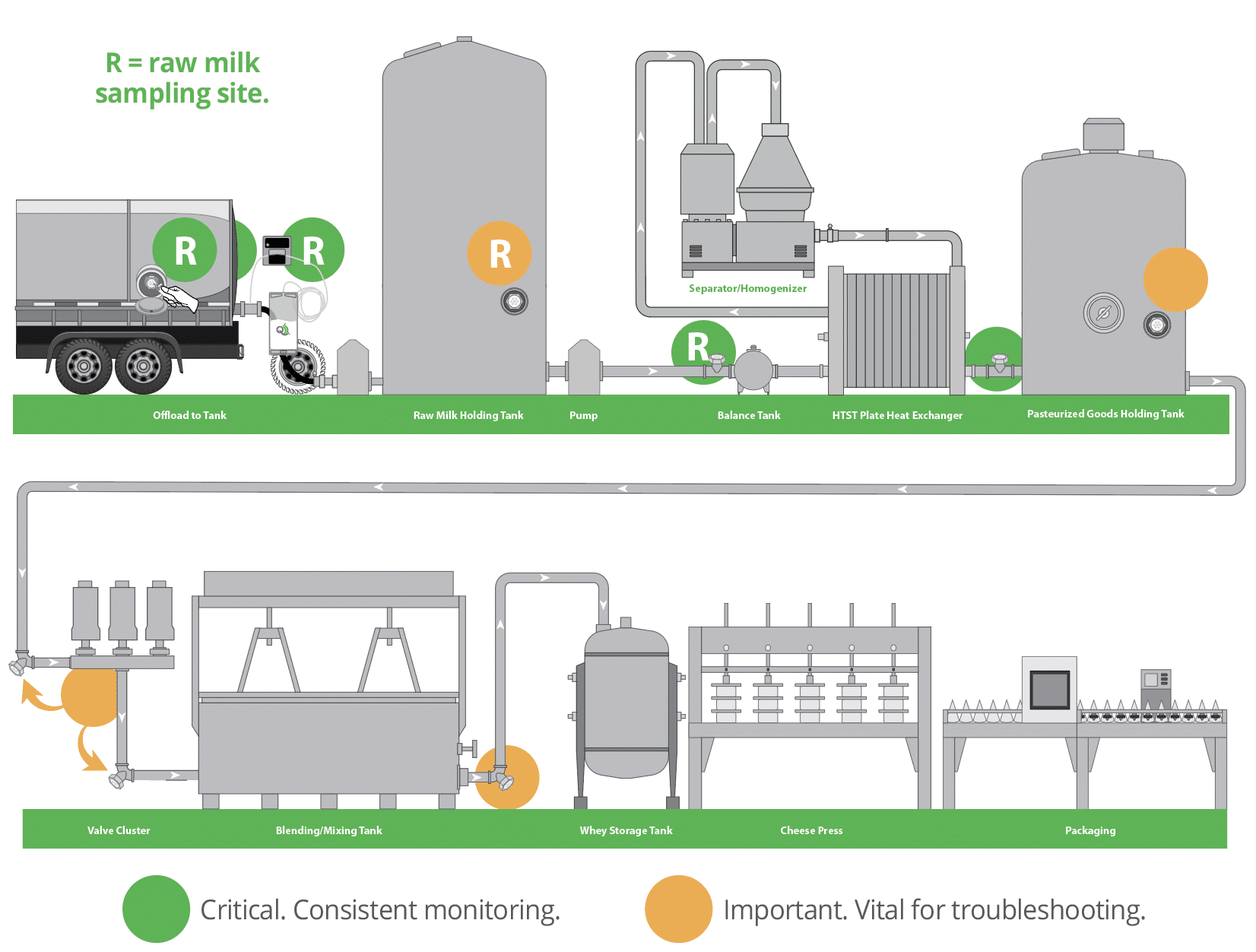

Sample collection for microbiological testing is conducted at CCPs throughout the cheese production process. These points include the raw milk receiving area, processing equipment, aging rooms, and finished product storage areas. For example, collecting samples from the pasteurizer helps verify the effectiveness of heat treatment in eliminating pathogenic bacteria and spores.

Raw milk quality is crucial in cheese production, especially for hard cheese makers who need to keep spore counts low to avoid late-blowing cheese caused by spore-forming bacteria that may survive pasteurization. Maintaining low coliform and total bacteria counts in raw milk is also key to producing quality cheese. Therefore, it is important to collect samples as the milk is received at the plant and follow up with samples from the balance tank of the pasteurizer. This comparison helps determine if bacterial loads increase during raw milk storage.

Additionally, sampling from the high-temperature short-time (HTST) pasteurizer discharge aids the quality control manager in identifying potential contamination from biofilms, cracks, and pinholes in the cooling section plates. When troubleshooting, isolating the cheese vats is valuable, so sampling should be conducted before the cheese vats and in the line carrying the whey to the storage tanks.

Implementing these comprehensive measures helps cheesemakers maintain high standards, ensure the safety of their products, and uphold the integrity of their cheese production processes.

Aseptic Sampling Site Recommendations for Cheese Quality Control

Most critical (Green): These are the most essential steps in the process that need consistent monitoring:

- Raw milk received at the cheese processing plant can be sampled directly from the tanker using a TruDraw® collection vial and/or, more appropriately, a larger sample should be collected using a TruMotion 2 liter Collection Bag and Watson-Marlow peristaltic pump as the milk is being offloaded from the tanker. Test results on these samples are used to i) determine if the raw milk is of sufficiently high quality for acceptance by the plant; ii) determine the level of thermoduric organisms, such as spore formers, that may survive pasteurization and contaminate finished product; and iii) provide a baseline as comparison with further tests.

- Raw milk from the balance tank of the pasteurizer should be sampled using a TruDraw collection vial injected through a TruStream sampling device positioned immediately ahead of the balance tank. Test results on these samples will be compared with those taken off the milk transport (above) and those at the HTST pasteurizer’s discharge.

- The HTST pasteurizer should be sampled at its discharge. Samples from this location should be free of bacteria. Any thermoduric lactic acid bacteria that survive pasteurization or remain in the pasteurizer can contribute to post-pasteurization contamination, particularly from the cooling section. Tests from these samples should be carefully analyzed for Gram-positive spore formers, Gram-positive lactic acid bacteria, Gram-negative psychrotrophic bacteria, and coliforms using the appropriate analytical techniques.

Vital for troubleshooting potential sources of cheese contamination (Gold): Sampling points shown in gold require monitoring if troubleshooting for post-pasteurization contamination becomes necessary. Ideally, sample collection ports should be installed in each raw and pasteurized milk holding silo; before and after each mixing or blending tank; before and after each valve cluster; and before and after each additional piece of equipment that may be in the process. This process allows each piece of equipment to be isolated and clearly shows where the post‑pasteurization contamination originates.

The journey towards exceptional cheese product quality begins at the farm and continues throughout the processing chain. QualiTru’s aseptic sampling systems deliver a reliable and efficient means for cheese plants to monitor milk quality for contaminants. By facilitating accurate, timely, and reliable sampling, QualiTru systems enable proactive interventions, helping to maintain the highest standards of cheese product safety and quality.

- Inline Sampling

- TruStream7 Tri-Clamp Tee 2” (Part #215147) or TruStream 7 Tr9-Clamp Elbow 2″ (Part #213029)

- TruStream7 Septa (Part # 110011)

- TruStream 250ml/18g (Part #111450) or TruMotion 2L/18g w/2.0mm Tubing (Part #111770) with a Watson-Marlow Pump (Part #500000) for a representative sample or the TruDraw® Sterile Single Sampler (Part #112021) for a small, aseptic sample

- Holding Tank Sampling

- TruStream7 Recessed 4”x 2” (Part #212123)

- TruStream7 Septa (Part #110011)

- TruDraw® Sterile Single Sampler (Part #112021)

Harness the Benefits of Aseptic Sampling and Eradicate Harmful Bacteria

Aseptic sampling is a critical component in maintaining the safety and quality of cheese. QualiTru sampling systems provide a cost-effective solution for aseptic sampling, allowing for accurate and contamination-free sampling at various stages of cheese production. The system ensures that samples are representative and reliable, helping producers monitor and control cheese contamination effectively.

Complete this form to have one of our experts contact you to discuss implementing aseptic inline sampling to monitor for cheese contamination as part of your process monitoring plan! Or call us at (651) 501-2337 or email [email protected] to learn more and/or to discuss your needs.