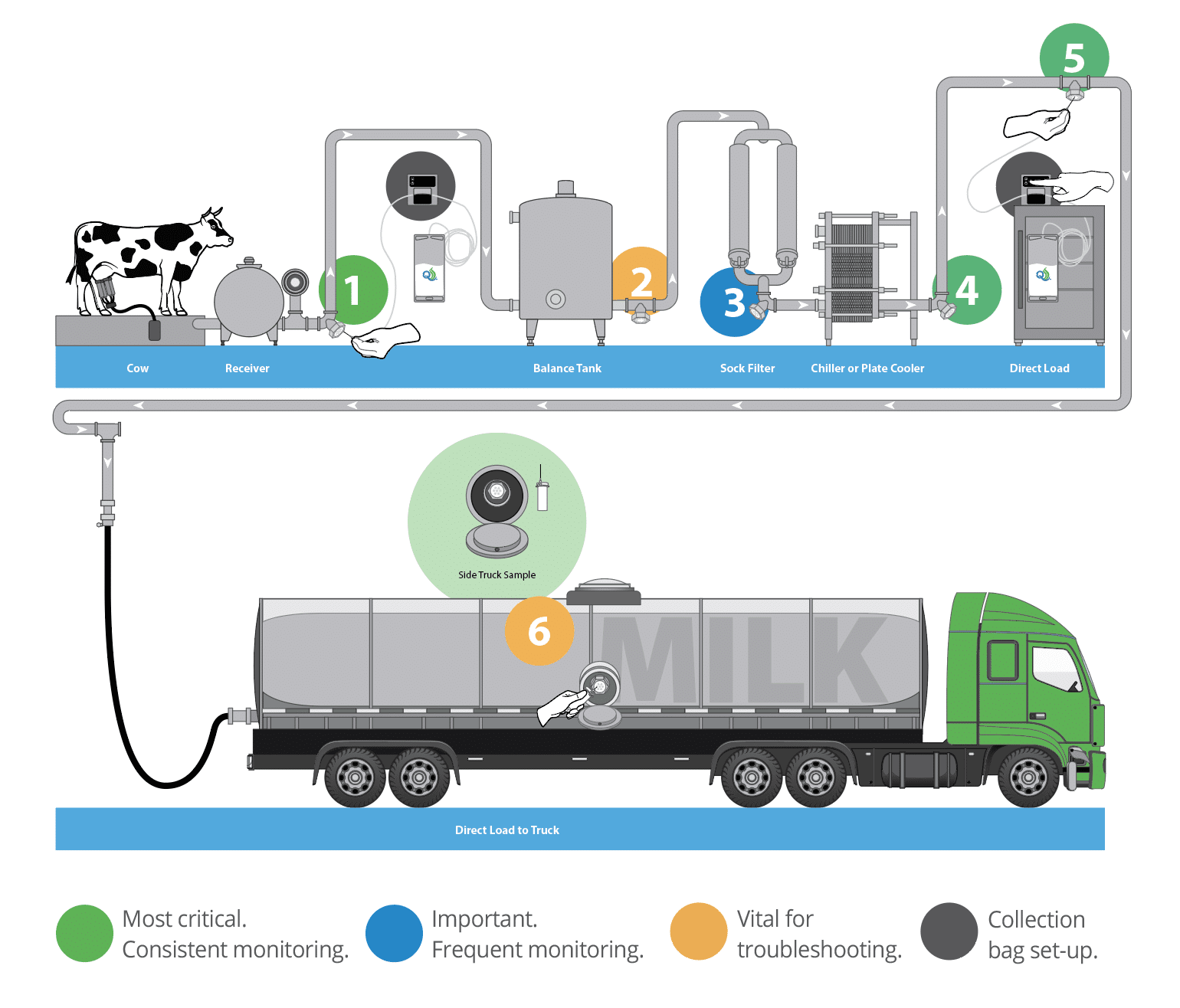

Direct load sampling is a critical concern for dairy farms using direct tanker loading (DTL) systems—a modern alternative to traditional bulk tanks. DTL reduces labor and energy costs while accommodating larger herd sizes, but it also eliminates agitation, making representative milk tanker sampling far more challenging.

In these systems, milk flows directly from the parlor into the tanker without passing through agitated storage, increasing the risk of stratification. Traditional sampling methods often miss this variability, leading to inaccurate test results—and potential revenue loss from underreported components.

Why Milk Tanker Sampling Without Direct Load Sampling Falls Short

Most tankers lack agitation, meaning milk can separate during loading. Fat rises, solids settle, and contaminating bacteria are often carried to the top of the load with the rising fat layer. Without agitation, a sample drawn from the top or bottom may not represent the actual composition or contamination level of the full load. This matters because producers are paid based on the tested components and bacterial quality of the milk. Inaccurate sampling can mean lower payments and smaller bonuses.

In many operations, samples are still collected manually by climbing atop the tanker. This is unsafe, unsanitary, and inaccurate. Open-air dip sampling also makes custody control difficult and can lead to disputes over milk quality or contamination sources.

These aren’t hypothetical concerns; they affect dairy operations every day. Large producers depend on reliable data and secure sampling to protect both product quality and payment integrity.

“The QualiTru inline sampling system with the peristaltic pump is the only aseptic sampling system on the market. It provides accurate and consistent results. The system is very simple to install, maintain, and operate. It is in use at several large farms for their direct loading operations and has been in use for over six years on some of those.

(Mark J Shelmidine, Senior Field Representative, Milk Quality Specialist, Dairy Farmers of America-Northeast Area)

How Direct Load Sampling Improves Sampling Safety and Accuracy

QualiTru’s inline sampling systems are purpose-built to address the sampling challenges in DTL systems. Installed directly in the milk transfer line upstream of the tanker, our systems deliver a truly representative, aseptic sample—collected safely and conveniently at ground level. Samples are pulled through pre-sterilized, single-use collection bags that eliminate the risk of introducing contamination into the sample and support full custody traceability.

With QualiTru, producers gain peace of mind knowing their samples accurately reflect the milk they produced—and that they’ll be compensated fairly for its quality.

Aseptic Sampling Site Recommendations for Direct Load Sampling

Most critical (Green): These are the most essential steps in the process that need consistent monitoring:

- String/Pen Sampling: Milk coming out of the receiver represents the commingled milk of the group of cows (string) currently being milked in the milking parlor. Samples should be collected at the receiver at least once for each string (sample with TruDraw® collection vial). Still, the best method is to collect the sample consistently throughout milking using a TruMotion™ 2-liter Collection Bag and Watson-Marlow peristaltic pump (or equivalent QualiTru peristaltic pump offering). Test results on these samples will help the dairy farm manager determine whether milking machines are clean and whether employees adequately sanitize udders before attaching the milking unit to the cow. Results can also help monitor the herd for mastitis by helping to identify and isolate infected cows.

- Sanitation Verification: Milk from the plate cooler (chiller) is the next critical control point (CCP). A sample should be collected immediately downstream of the plate cooler. This sample will indicate whether the equipment was properly cleaned and sanitized. If contamination increases from the receiver to this sampling point, the equipment is likely soiled, or biofilms may be present at some point in the process. This sample should be collected early in the milking of each string using a TruDraw sampling vial or equivalent.

- Direct Load Sampling: Milk being loaded directly onto the milk tanker is the final step before the milk leaves the farm. The farm manager should want this sample collected to ensure the bulk tank is cleaned correctly and as evidence of the quality of the milk that is being released to the dairy processor. This sample should be collected over the entire course of loading using a TruMotion Collection Bag and peristaltic pump.

Important. Frequent monitoring (Blue): Collecting a sample immediately upstream of the plate cooler is valuable. This is done for an important reason: to isolate the plate cooler. Occasionally, cracks or pinholes develop in cooler plates, or gaskets become worn and cracked. These defects can allow contaminants to enter the milk from the water or glycol coolant used to chill the milk.

Milk is cooled in the plate cooler as it runs over one side of a thin stainless steel plate with very cold chill-water or water plus glycol coolant running on the other side in counter-current flow. Theoretically, the pressure on the milk side of the plate is higher, so if a leak occurs, milk will flow in the direction of the coolant rather than the other way around. However, this pressure gradient is often improperly maintained due to operator inattention or a change in flow from a pump. Monitoring for this potentiality is valuable for troubleshooting but not critical daily.

A sample from this location should be taken using a TruDraw sampling vial or equivalent. The sample should be collected early in the milking of the first string, and results should be compared to the sample collected downstream of the chiller.

Vital for troubleshooting potential sources of cheese contamination (Gold): Sampling points shown in gold require monitoring if troubleshooting for post-pasteurization contamination becomes necessary. Ideally, sample collection ports should be installed in each raw and pasteurized milk holding silo; before and after each mixing or blending tank; before and after each valve cluster; and before and after each additional piece of equipment that may be in the process. This process allows each piece of equipment to be isolated and clearly shows where the post‑pasteurization contamination originates.

The journey toward exceptional milk quality starts in the parlor and continues through every stage of handling—including direct load operations. QualiTru’s aseptic sampling systems provide a reliable, efficient way to collect accurate, representative samples during DTL. By enabling safe, inline sampling at ground level, our systems help dairy producers verify milk quality, support regulatory compliance, and protect the integrity of their product from farm to processor.

- Direct Load Sampling

- TruStream7 Tri-Clamp Tee 2” (Part #215147) or TruStream 7 Tr9-Clamp Elbow 2″ (Part #213029)

- TruStream7 Septa (Part # 110011)

- TruMotion 2L/18g w/2.0mm Tubing (Part #111770) with a Watson-Marlow Pump (Part #500000) for a representative sample or the TruDraw® Sterile Single Sampler (Part #112021) for a small, aseptic sample

- Holding Tank Sampling

- TruStream7 Recessed 4”x 2” (Part #212123)

- TruStream7 Septa (Part #110011)

- TruDraw® Sterile Single Sampler (Part #112021)

- Appendix N Sampling

- TruDraw® Sterile Single Sampler (Part #112021)

- TS7 Adjustable Tanker Port with Security Lid (Part #212533)

Ready to Improve Sampling Safety and Accuracy?

When it comes to direct load sampling, precision matters. Don’t risk lost premiums, inconsistent data, or driver safety. QualiTru’s inline milk tanker sampling systems provide secure, ground-level access to aseptic, representative samples that support both accuracy and full custody traceability. It’s a smarter, safer way to protect your milk—and your bottom line.

Connect with a QualiTru specialist today to explore the best direct load sampling system for your farm.

To learn more or to order please call 651-501-2337 or email us at [email protected].