The Crucial Role of Raw Milk Microbial Testing in Producing High-Quality Dairy Products

The dairy industry globally strives to meet high-quality standards for processed products. One key to achieving this is raw milk microbial testing, a meticulous monitoring process that examines raw milk’s microbiological parameters. In this blog, we review the significance of these parameters, including somatic cell counts (SCC) and bacterial counts, and their direct impact on the quality of processed dairy products. We also explore strategies for dairy farms to enhance milk quality, helping to ensure safe and high-quality dairy products for consumers.

Optimizing Dairy Operations with Somatic Cell Count Management

SCC is more than just a measure of milk quality—it is a multifaceted indicator that affects almost every aspect of dairy operations. Elevated SCC is often indicative of mastitis, affecting milk’s flavor, shelf life, and processing qualities. (Martin et al., 2023) Therefore, managing SCC effectively is critical for maintaining milk quality and the overall profitability of the dairy farm. A lower Bulk Tank Somatic Cell Count (BTSCC) not only signals healthy mammary function but also presents an excellent opportunity to enhance profits.

By keeping the SCC in check, dairy producers can improve the milk’s flavor, extend its shelf life, and optimize processing outcomes, ensuring that the milk meets stringent industry standards. With raw milk microbial testing, the industry can continue to ensure that every step of the dairy process contributes to producing superior products and maximizing operational returns.

Read our earlier post, Somatic Cell Counts (SCC) Impact on Dairy Farmers, to better understand how lowering SCC leads to increased profits.

Milk Stratification and Sampling Challenges

The natural process of raw milk stratification can lead to sampling and testing issues, as the cream carrying bacterial and somatic cells rises to the top of the bulk tank. Without thorough agitation, dipper sampling from the top can result in elevated bacteria and SCC test results. However, agitation alone may not suffice. QualiTru’s peristaltic pump sampling procedure leads to more accurate and consistent laboratory test results by ensuring more effective and representative sampling. This mitigates the risk of inaccurate cell count measures that can affect testing accuracy and farm profits.

Bacterial Counts and Their Impact

Equally critical to milk quality are the bacterial counts, including total bacterial count (TBC), psychrotrophic bacteria count, and specific pathogen monitoring. These counts offer insights into the milk’s microbial load, which can influence spoilage rates, fermentation processes, and the safety of dairy products. As discussed in the referenced study, the guidelines for monitoring bulk tank milk somatic cell and bacterial counts underline the importance of maintaining low bacterial counts to achieve superior quality dairy products. (Ralyea et al., 2023) By adhering to stringent bacterial standards, dairy processors can prevent spoilage, extend shelf life, increase profits, and ensure the safety and taste of dairy products.

Controlling Spore-Forming Bacteria for Extended Shelf Life

The trend towards pasteurized milk with an extended shelf life demands careful control of spore-forming bacteria at the farm level. The spoilage caused by psychrotolerant spore-formers post-pasteurization necessitates meticulous bacterial management. Bacteria in pasteurized milk can be a cause of spoilage and reduced shelf life. Therefore, continuous monitoring and controlling at the source is paramount for high-quality end products.

Regulatory Standards and Grade A Status

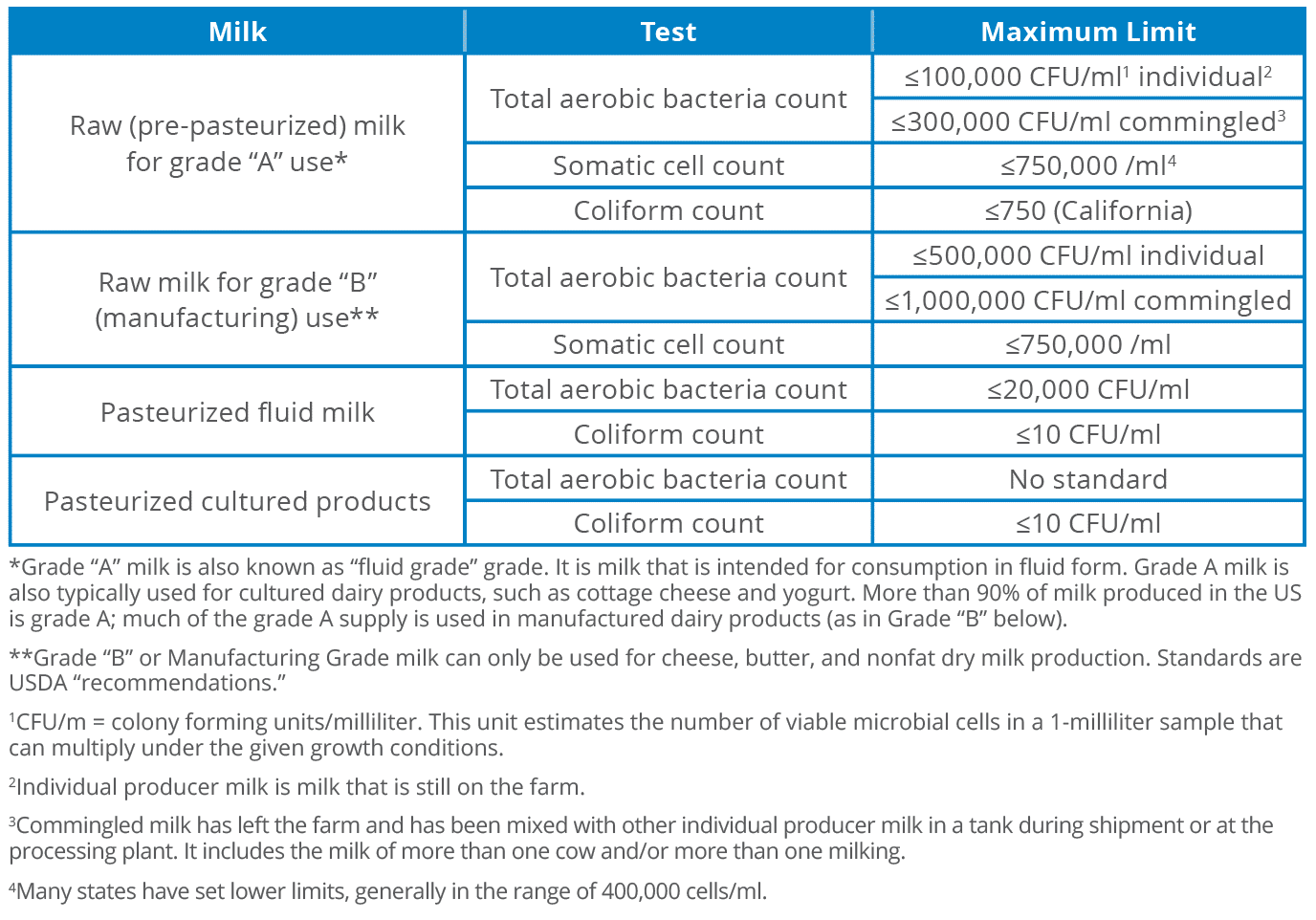

Farm testing of milk for low bacteria count is not just about quality but also about compliance with regulatory standards. Maintaining a Grade A status is essential for premium payment and requires adherence to strict bacterial limits. The regulation of milk quality, encompassing both raw and pasteurized products, is governed by the Grade “A” Pasteurized Milk Ordinance (PMO). Regulatory bodies recognize the direct correlation between farm-level testing and the safety and quality of dairy products, thereby enforcing such measures. Beyond microbiological metrics, the quality measures for milk are multifaceted. Milk must be free of drug residues like antibiotics, contain no added water, and be devoid of sediment and other contaminants.

To maintain quality and consumer brand expectations, some dairy processors pay premiums for higher quality raw milk, providing incentives for farmers to improve hygiene on the farm. Implementing QualiTru’s representative string sampling for component verification is a proven method for dairy farmers to capture premium payments and increase profitability.

Microbiological Quality Standards for Raw and Pasteurized Milk

Quality Assurance through Raw Milk Microbial Testing

Microbiological monitoring, involving the regular assessment of SCC and bacterial counts, is essential for identifying milk quality issues at an early stage. Sampling systems, such as QualiTru’s string sampling system, enable accurate and representative sampling of raw milk, facilitating effective monitoring and timely intervention. By identifying and addressing the sources of microbial contamination, dairy farms can significantly improve the overall quality of raw milk.

Read our earlier post, Economics of Quality Assurance in Dairy Processing, to read about the eight key economic aspects related to quality assurance in this industry.

Implementing Innovative Practices for Improved Milk Quality

To mitigate the challenges posed by high SCC and bacterial counts, dairy farms are encouraged to adopt innovative practices. These include meticulous udder hygiene, effective mastitis control strategies, sanitary milking practices, and the implementation of sampling systems for precise microbiological analysis. By embracing these practices, dairy farms not only enhance milk quality but also contribute to the sustainability and profitability of the dairy industry.

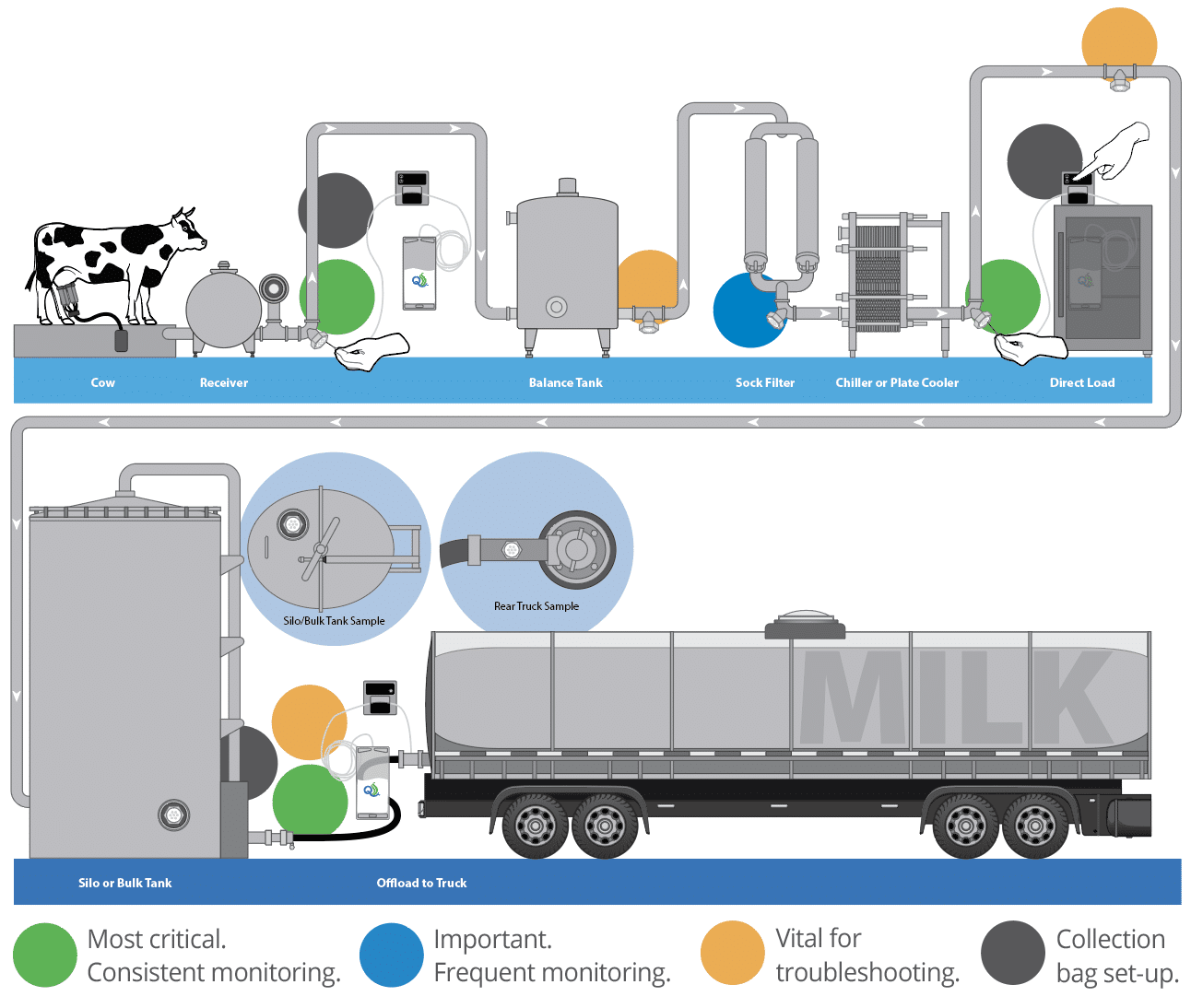

Maintaining the microbiological quality of raw milk is challenging, and process monitoring is a critical element. Microbiological sampling at critical control points (CCP) in the process helps dairy farm managers control contamination, validate cleaning and sanitation procedures, and identify sources of raw milk contaminants. QualiTru TruStream™ sampling devices should be placed at these critical locations.

The following is a breakdown of potential CCPs on a dairy farm.

Most critical (Green): These are the most essential steps in the process that need consistent monitoring:

- Milk coming out of the receiver represents the commingled milk of the group of cows (string) currently being milked in the milking parlor. Samples should be collected at the receiver at least once for each string (sample with TruDraw® collection vial). Still, the best method is to collect the sample consistently throughout milking using a TruMotion™ 2 liter Collection Bag and Watson-Marlow peristaltic pump (or equivalent QualiTru peristaltic pump offering). Test results on these samples will help the dairy farm manager determine whether milking machines are clean and employees adequately sanitize udders before attaching the milking unit to the cow. Results can also help monitor the herd for mastitis by helping to identify and isolate infected cows.

- Milk from the plate cooler (chiller) is the next CCP. A sample should be collected immediately downstream of the plate cooler. This sample will indicate whether the equipment was properly cleaned and sanitized. If contamination increases from the receiver to this sampling point, the equipment is likely soiled, or biofilms may be present at some point in the process. This sample should be collected early in the milking of each string using a TruDraw sampling vial or equivalent.

- Milk coming out of the bulk tank or being loaded directly onto the milk tanker is the final step before the milk leaves the farm. The farm manager should want this sample collected to ensure the bulk tank is cleaned correctly and as evidence of the quality of the milk that is being released to the dairy processor. This sample should be collected over the entire course of loading using a TruMotion Collection Bag and peristaltic pump.

Important. Frequent monitoring (Blue): Collecting a sample immediately upstream of the plate cooler is valuable. This is done for an important reason: to isolate the plate cooler. Occasionally, cracks or pinholes develop in cooler plates, or gaskets become worn and cracked. These defects can allow contaminants to enter the milk from the water or glycol coolant used to chill the milk.

Milk is cooled in the plate cooler as it runs over one side of a thin stainless steel plate with very cold chill-water or water plus glycol coolant running on the other side in counter-current flow. Theoretically, the pressure on the milk side of the plate is higher, so if a leak occurs, milk will flow in the direction of the coolant rather than the other way around. However, this pressure gradient is often improperly maintained due to operator inattention or a change in flow from a pump. Monitoring for this potentiality is valuable for troubleshooting but not critical daily.

A sample from this location should be taken using a TruDraw sampling vial or equivalent. The sample should be collected early in the milking of the first string, and results should be compared to the sample collected downstream of the chiller.

Vital for troubleshooting potential sources of contamination (Gold): Sampling locations at various points along the process should be established so equipment can be isolated. For example, a sampling port after the balance tank will isolate the process from the receiver through the balance tank. A sampling port before the bulk tank will isolate transfer lines from the chiller to the bulk tank, and so on. This sampling method is valuable in troubleshooting contamination problems by narrowing down where contamination might originate. It is tough to identify sources of contamination unless the process can be broken down into small segments.

Similarly, a sampling port in the door of the bulk tank (or silo) will isolate the bulk tank. Large vessels, such as bulk tanks or milk silos, are challenging to clean and are subject to failure in the stainless steel leading to cracks or pitting that can harbor bacterial contaminants. Biofilms readily attach to pitted or cracked stainless steel; once established, they are challenging to find and eradicate.

The Role of String Sampling for Quality Assurance

The microbiological parameters of raw milk, particularly somatic cell and bacterial counts, play a crucial role in determining the quality of processed dairy products. Through diligent monitoring and the adoption of best practices in milk production, the dairy industry can ensure the delivery of safe, high-quality products to consumers. The integration of string sampling and peristaltic pump procedures into quality assurance programs further empowers dairy farms to achieve and maintain high standards of milk quality, reinforcing the industry’s commitment to excellence and consumer safety.

Elevate your production standards today. Contact QualiTru Sampling Systems to integrate our sampling solutions into your process and ensure the quality and safety that your customers deserve. Reach out to become a part of the QualiTru success story.

1. Martin, N. H., Evanowski, R. L., & Wiedmann, M. (2023). Invited review: Redefining raw milk quality-Evaluation of raw milk microbiological parameters to ensure high-quality processed dairy products. Journal of Dairy Science, 106(3), 1502–1517. https://doi.org/10.3168/jds.2022-22416 2. Ralyea, R., Wiedmann, M., & Boor, K. J. (2023). Microbial Testing in Raw Milk: Quality Enhancement for Dairy Processing. Journal of Dairy Research, 90(2), 245–259. https://pubmed.ncbi.nlm.nih.gov/27665134/