Economics of Quality Assurance in Dairy Processing

A cost-benefit analysis of a well-conceived and carefully sustained quality assurance program for dairy processing is hard to pin down. Every month, the costs associated with maintaining quality assurance jump off the profit and loss statement, but the benefits are much harder to decipher. Still, when evaluating the economics of quality assurance over the long term it is clear the benefits far outweigh the costs.

Key Factors that Influence the Economics of Quality Assurance in Dairy Processing

Quality assurance in dairy processing is crucial for various reasons, including product safety, consumer satisfaction, and regulatory compliance. Here are the key economic aspects related to quality assurance in this industry:

- Avoiding Product Recalls: In 2022 alone, the U.S. Food and Drug Administration (FDA) reported 24 cases of dairy-related quality failures resulting in product recalls1. Implementing robust quality assurance measures helps avoid costly product recalls associated with quality failures. The cost of product recalls can be substantial—often reaching tens of millions of dollars—and may include expenses for product disposal, legal liabilities, increased insurance costs, and damage to brand reputation.

- Risk Mitigation: Careful implementation of a quality assurance plan helps mitigate risks, such as bacterial contamination causing spoilage or foodborne disease. Product recalls, plant shutdowns, production disruptions, and costly extra cleaning procedures may be avoided by preventing issues before they escalate.

- Customer Satisfaction and Brand Reputation: Maintaining consistent product quality ensures that consumers can trust the brand. This consistency leads to brand loyalty, repeat customers, and increased sales, positively impacting revenue and bottom line.

- Higher Efficiency, Less Waste: A well-conceived quality assurance plan can improve production efficiency by identifying and addressing process inefficiencies and equipment failures early. This can lead to cost savings in terms of reduced raw material wastage, energy consumption, and labor costs. In addition, lower bacterial content and better handling practices can help extend dairy product shelf life, leading to fewer unsaleable or returned products. Finally, better dairy quality can enhance yield and improve efficiency. For example, higher-quality milk may augment cheese curd formation and enable easier, faster processing that increases efficiency, improves production, and results in higher yields for processors.

- Market Access: Consistently high-quality products augment a milk processor’s reputation, potentially opening or expanding new market access and export opportunities. Many countries have stringent regulations for dairy imports based on product quality. Maintaining high product quality standards helps ensure compliance with such regulations.

- Competitive Advantage: High-quality dairy products can command premium prices in the market. Good quality helps differentiate products and justifies higher prices, potentially increasing revenue and profit margins.

- Regulatory Compliance: Non-compliance with quality and safety regulations can result in fines, legal penalties, and disruptions in distribution. Investing in quality assurance measures ensures adherence to these regulations, preventing potential economic loss.

- Supply Chain Efficiency: Ensuring the quality of raw milk and other materials or ingredients through supplier quality control can reduce the risk of supply chain disruptions that can be costly in terms of production delays, increased transportation, and added labor costs, and that can be a source of finished product contamination if left unchecked.

Maintaining high quality is essential for milk processors to remain competitive, improve profitability, and establish or maintain a strong foothold in domestic and international markets. Failure to maintain dairy quality can lead to economic losses, reduced competitiveness, and potential damage to a company’s reputation.

From this, it is clear the economics of quality assurance in dairy processing are multifaceted and not directly translatable to near-term profitability. Instead, they encompass cost savings, revenue enhancement, risk mitigation, and regulatory compliance. Implementing effective quality assurance measures is an investment that yields significant economic benefits over the long term. While implementation involves direct expenses related to testing, equipment, and personnel, the benefits of improved product quality and reduced risks far outweigh these costs.

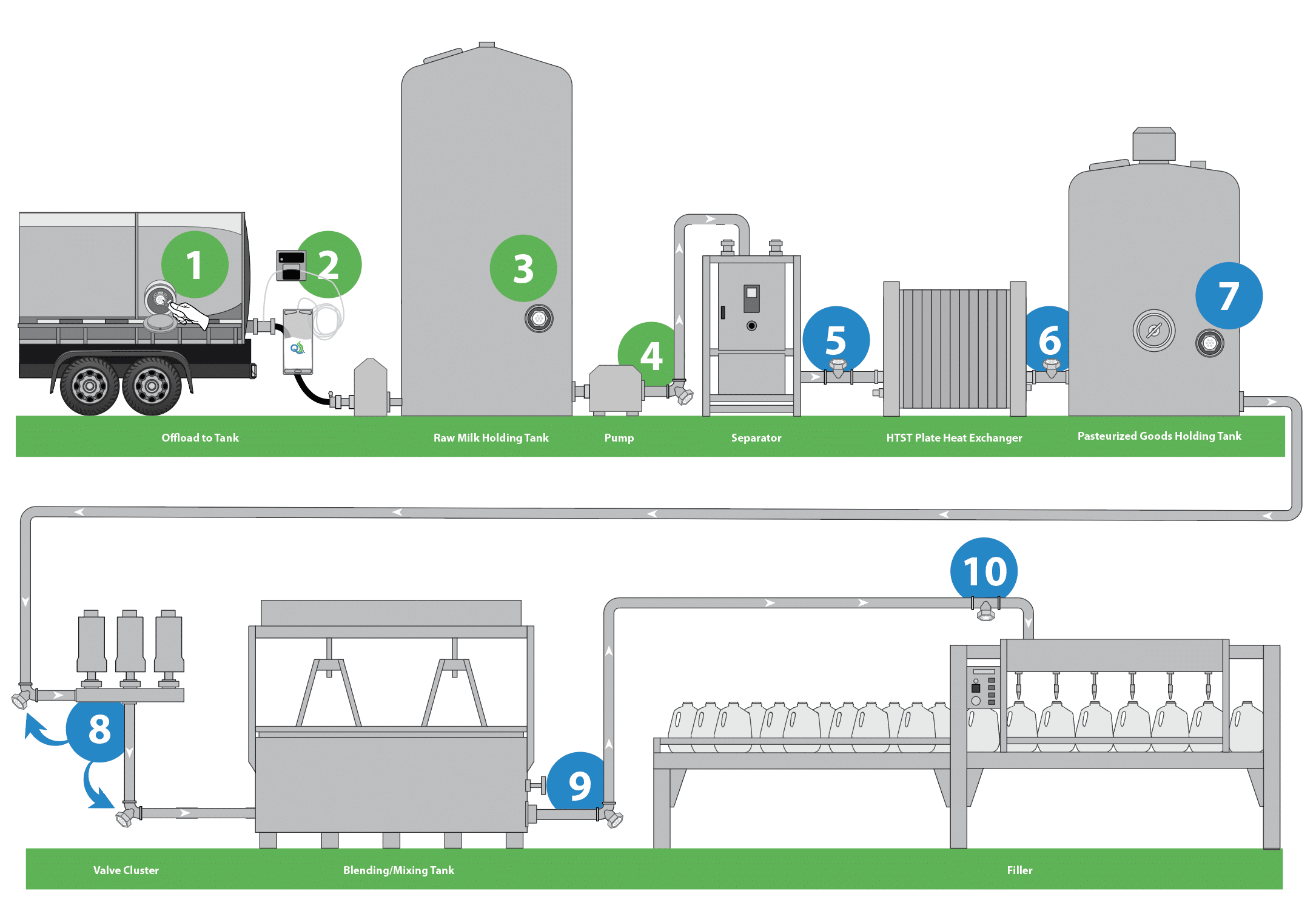

Contamination by spoilage or disease-causing bacteria is often transient and difficult to isolate. The only sure way to find and control bacterial contaminants in a dairy processing environment is to isolate contamination hotspots and uncover contamination as it occurs. This requires careful monitoring of each step in the production process. For more information, see our white paper, Process Monitoring to Ensure Dairy Quality and Safety.

QualiTru Can Help Optimize Quality Management

The quality of finished dairy products starts on the farm and carries through processing. A well-conceived quality assurance program will aid profitability by ensuring good quality raw milk supplies and ingredients, catching post-pasteurization contaminants before they can inflict damage to revenue or brand reputation, uncovering hidden problems with processing procedures or equipment, and assessing the efficacy of hygiene programs.

Since 1983, the dairy industry has relied on QualiTru® Sampling Systems to provide fast, simple, safe, and accurate samples for bacterial and chemical quality analysis. A low cost per sample allows QualiTru’s sampling systems, such as the TruStream Septa and TruStream Ports, to be used widely on the farm and at every step in processing to help ensure the consistently high-quality inline process monitoring needed in today’s dairy processing environment.

[1] U.S. Food & Drug Administration. Recalls, Market Withdrawals, & Safety Alerts. www.fda.gov/safety/recalls-market-withdrawals-safety-alerts.

Resources

QualliTru Applications and Product Guide

FAQs

Best Practices for Using Your QualiTru Septum

Printable Site Application Schematics

Implementing hygienic sampling practices is easy with QualiTru’s aseptic and representative sampling system.

Have questions about aseptic and representative sampling? Ask Our Experts