NoLo Beer Trends and Issues with Beer Spoilage Bacteria

The NoLo beer segment is experiencing significant growth, with a 40% increase in sales in recent years. (Howarth, J., 2024) This trend is part of a broader shift in the beverage industry towards healthier options and diversified product lines. According to Beverage Industry, the low- and no-alcohol category is spearheading market growth, with more consumers seeking healthier alternatives that still offer the social and sensory experience of traditional alcoholic beverages. As more breweries and non-alcoholic beverage manufacturers enter the NoLo market, combating beer spoilage bacteria becomes essential to maintaining product quality and safety. (Jacobsen, J., 2023)

NoLo Beers Present a Unique Challenge in Beer Quality Control

NoLo beers are distinct from their alcoholic counterparts due to their reduced alcohol content, which inherently provides less protection against microbial contamination. The absence of sufficient ethanol levels, combined with lower concentrations of hop-derived antimicrobial compounds, creates an environment where beer spoilage bacteria can thrive. (Roselli, G.E. et al, 2024) Understanding and controlling these microbes are essential for ensuring the quality and safety of NoLo beers.

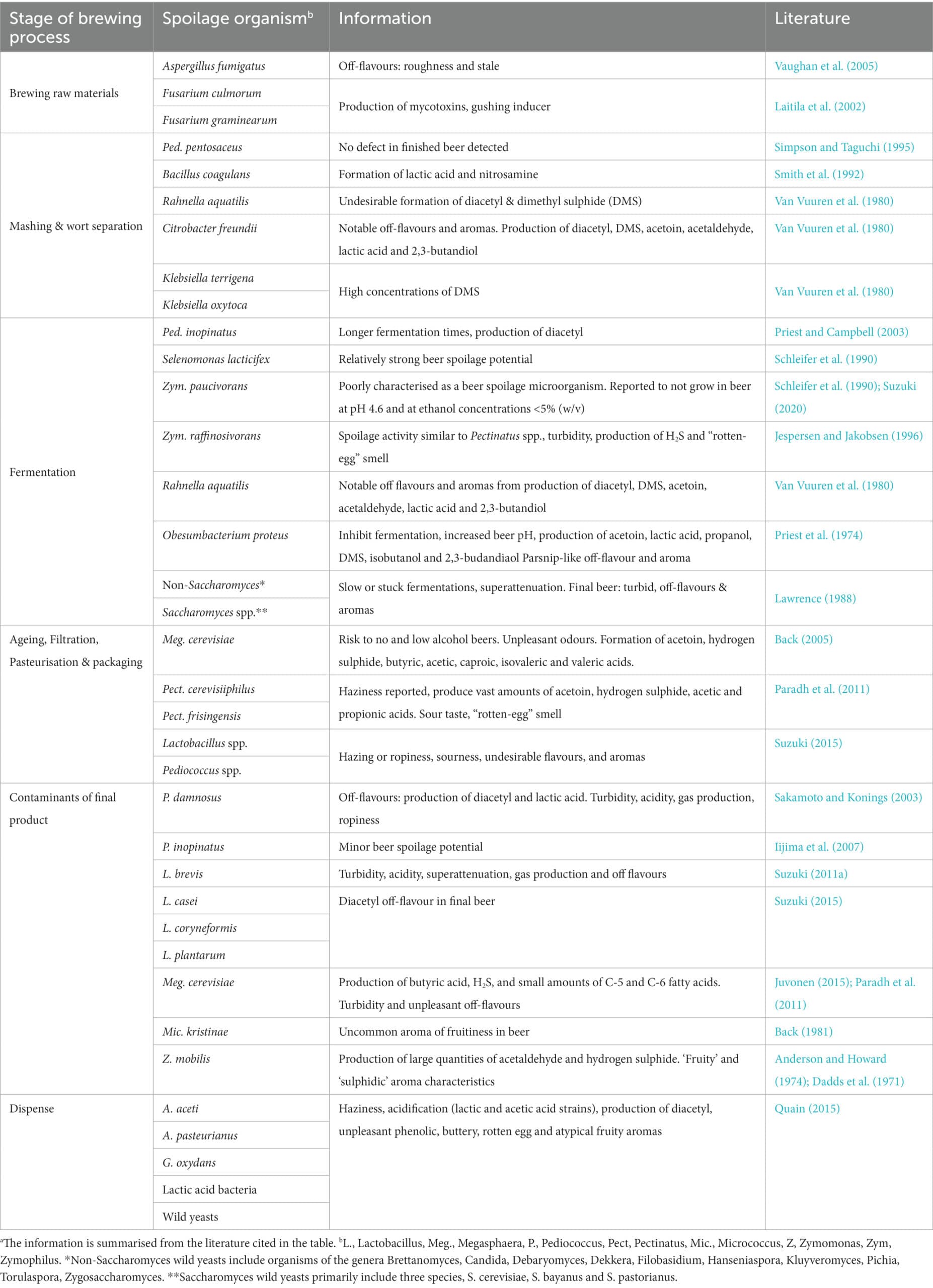

Key Microbes in Alcoholic Beverages to Monitor

To maintain the quality and safety of NoLo beers, it is imperative to monitor and control various spoilage microorganisms. The following microbes are of particular concern:

- Lactic Acid Bacteria (LAB): These bacteria, including species such as Lactobacillus and Pediococcus, are common spoilage agents in brewing. They produce lactic acid, which can result in sour off-flavors and spoilage.

- Wild Yeasts: Non-saccharomyces yeasts like Brettanomyces can cause unwanted fermentation, leading to off-flavors and over-carbonation.

- Acetic Acid Bacteria (AAB): Species such as Acetobacter can produce acetic acid, contributing to vinegar-like off-flavors.

- Enterobacteriaceae: This family of bacteria includes various spoilage organisms that can produce undesirable compounds and cause beer spoilage.

- Molds: Fungi such as Aspergillus and Penicillium can contaminate raw materials and the brewing environment, leading to spoilage and potential mycotoxin production.

Common beer spoilage species and their effects on beer.

The Importance of Water Quality Sampling

Water quality is a cornerstone of beer production, influencing everything from the brewing process to the final product. In NoLo beers, maintaining optimal water quality is even more crucial due to their reduced microbial defenses. Effective water sampling and quality control practices are essential to prevent microbial contamination and ensure the safety of NoLo beers.

Key Factors in Water Quality Sampling:

- Detection of Contaminants: Regular sampling helps in the early detection of microbial contaminants such as bacteria, fungi, and viruses, which can compromise the safety and quality of the beer.

- Consistency in Quality: By monitoring water quality consistently, breweries can ensure that the beer produced maintains the desired flavor profile and quality standards.

- Chemical Contaminants: Monitoring for chemicals such as chlorine, heavy metals, and pesticides that can affect beer flavor and safety is an essential aspect of sampling.

- Physical Contaminants: Sampling helps identify the presence of particulates and sediments that can impact the brewing process and product quality.

Strategies for Combating Beer Spoilage Bacteria

To ensure the microbial safety of NoLo beers, it is essential for breweries to adopt stringent monitoring and control practices. Here are some recommended strategies:

- Regular Sampling and Testing: Implementing routine sampling and testing protocols is essential for early detection of microbial contaminants. Utilizing advanced molecular methods, such as quantitative polymerase chain reaction (qPCR), can provide rapid and accurate identification of spoilage organisms.

- Sanitation and Hygiene: Maintaining high standards of cleanliness in the brewing environment is critical. This includes regular cleaning and sanitization of equipment, surfaces, and containers.

- Quality Control of Raw Materials: Ensuring the microbial quality of raw materials, such as malt and hops, is vital to prevent contamination from the source.

- Temperature and pH Control: Monitoring and controlling fermentation conditions, including temperature and pH, can help inhibit the growth of spoilage microbes.

The Role of QualiTru in Ensuring NoLo Beer Quality Control

At QualiTru Sampling Systems, we understand the critical importance of microbial safety in the brewing industry. Our unique sampling systems are designed to provide reliable and accurate sampling solutions, helping breweries maintain the highest standards of beer quality control. Whether you are producing traditional beers or innovative NoLo products, our systems offer the precision and efficiency needed to safeguard your brews against microbial contamination.

Contact us at (651) 501-2337 or click below today to learn more about our advanced sampling solutions and how they can help you maintain the highest standards in your brewing operations.

References

Howarth, J. (2024) 6 important alcohol industry trends (2024-2027), Exploding Topics. Available at: https://explodingtopics.com/blog/alcohol-industry-trends (Accessed: 17 May 2024).

Jacobsen, J. (2023) Low/no alcohol spearheading growth for market, Beverage Industry RSS. Available at: https://www.bevindustry.com/articles/96276-low-no-alcohol-spearheading-growth-for-market.

Roselli, G.E. et al. (2024) The two faces of microorganisms in traditional brewing and the implications for no- and low-alcohol beers, Frontiers. Available at: https://www.frontiersin.org/journals/microbiology/articles/10.3389/fmicb.2024.1346724/full.