Managing Post-Pasteurization Risk

In dairy production, pasteurization is a critical process step, but it’s not the end of the risk. Once product exits the pasteurizer, it is vulnerable to post-pasteurization contamination (PPC) from environmental exposure, biofilm formation, equipment defects, or handling errors. Such contamination is often intermittent and symptomless, making it challenging to detect solely through end-product testing. In-process sampling (also known as line sampling) offers a more effective approach to identifying these risks early, before they compromise product quality or safety.

In-Process Sampling for Real-Time Visibility After the Pasteurizer

The most effective way to detect and mitigate PPC is through targeted, in-process sampling at critical process points after pasteurization. Unlike grab samples or tank sampling, in-process sampling captures product as it flows through the process piping, offering an accurate representation of production conditions. When performed aseptically, in-process sampling provides quality assurance (QA) teams with highly reliable data for verifying hygienic design, monitoring biofilm development, and validating clean-in-place (CIP) and sanitation programs.

Frequently Asked Questions About In-Process Sampling

Q: What is in-process sampling in dairy plants?

In-process sampling is the collection of milk samples at multiple points throughout the production process. When combined with proper testing procedures, in-process sampling allows dairy processors to catch contamination early, isolate sources of PPC, verify sanitation effectiveness, and maintain compliance with food safety regulations.

Q: How does in-process sampling help prevent post-pasteurization contamination?

Post-pasteurization contamination occurs when milk is exposed to bacteria after heat treatment. In-process sampling identifies contamination hotspots—such as plate coolers, valves, or pipelines—so plants can take corrective action before contaminated milk reaches storage tanks or leaves the facility.

Q: Is there a difference between in-process sampling and line sampling?

There is no major distinction and the terms are often used interchangeably. At QualiTru, line sampling refers to our aseptic sampling solutions installed directly on milk pipelines. Whereas in-process sampling may include installations on storage tanks or other processing equipment.

Q: What regulations do QualiTru’s sampling systems support?

QualiTru’s sampling systems meet requirements of the Pasteurized Milk Ordinance (PMO) Appendix N, 3-A Sanitary Standards, and Hazard Analysis and Critical Control Points (HACCP) programs. They also support Food Safety Modernization Act (FSMA) compliance and the National Conference on Interstate Milk Shipments (NCIMS) export requirements by providing a means for obtaining traceable, verifiable testing data.

Q: What equipment do I need for in-process sampling?

A complete system typically includes TruStream Sampling Ports, TruStream Septa, and TruStream Collection Bags or TruDraw® Sterile Single Samplers. QualiTru’s solutions are pre-sterilized and easy to install on existing milk lines for safe, contamination-free sample collection.

Aseptic Access Without Process Disruption

QualiTru sampling systems enable dairy processors to collect representative samples aseptically during processing without halting production. Designed for sterile access, our sampling systems are compatible with both manual and automated sampling procedures. In-process sampling can be used for routine pathogen surveillance, quality verification, or root cause analysis when microbial issues are detected downstream.

Start Sampling Smarter

Don’t wait for a quality issue to become a crisis. Post-pasteurization contamination is preventable, but only when it can be detected. QualiTru sampling systems give your QA team the tools to see beyond the pasteurizer and maintain control throughout the process. Act proactively, protect product quality, and maintain consumer trust.

Standard Operating Procedures (SOPs)

Consistent, reliable results depend on proper technique. QualiTru’s detailed SOPs and questionaire guide your team through installation, aseptic handling, and testing best practices, helping ensure every sample you collect is accurate, compliant, and representative.

Ready to strengthen your contamination prevention program?

Call 651-501-2337 to talk with a QualiTru sampling specialist today and learn how to integrate our sampling systems into your plant for safer, more consistent dairy production. Or email us at [email protected] for more information.

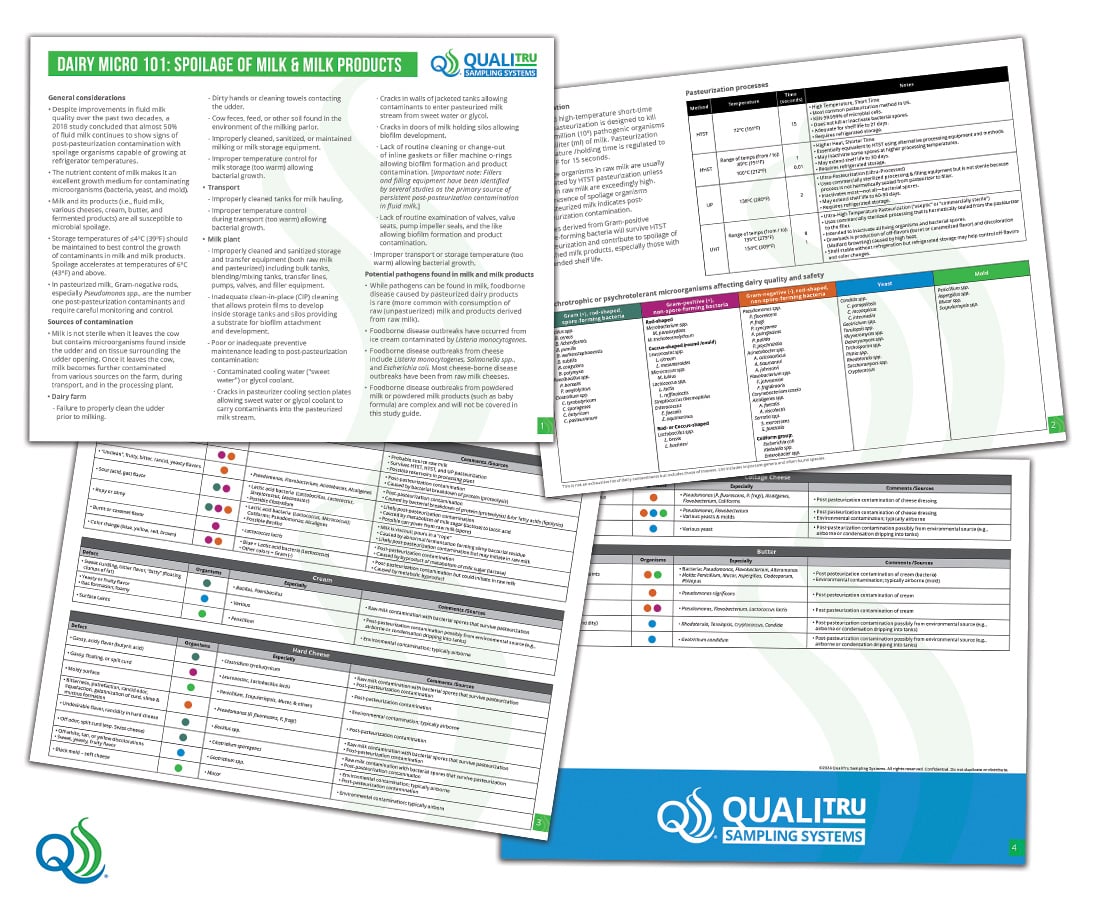

Download Our FREE Micro‑Spoilage Chart

Quickly identify common post‑pasteurization spoilage organisms and safeguard your products with our free “Dairy Micro 101: Spoilage of Milk & Milk Products Guide.” This chart includes color-coded references for psychrotrophic and psychrotolerant microbes, helping your team diagnose quality issues with confidence.

QualiTru’s aseptic in-process sampling systems offer a trusted, efficient solution for dairy plants to monitor product quality and detect potential contaminants in real time. By enabling accurate, timely, and representative sampling, QualiTru helps processors identify issues early, validate cleaning effectiveness, and uphold the highest standards of safety and consistency from line to loadout.

- Inline Sampling

- TruStream7 Tri-Clamp Tee 2” (Part #215147) or TruStream 7 Tr9-Clamp Elbow 2″ (Part #213029)

- TruStream7 Septum (Part # 110011)

- TruStream 250ml/18g (Part #111450) or TruMotion 2L/18g w/2.0mm Tubing (Part #111770) with a Watson-Marlow Pump (Part #500000) for a representative sample or the TruDraw® Sterile Single Sampler (Part #112021) for a small, aseptic sample

- Holding Tank Sampling

- TruStream7 Recessed 4”x 2” (Part #212123)

- TruStream7 Septum (Part #110011)

- TruDraw® Sterile Single Sampler (Part #112021)