Why is Aseptic Inline Sampling Critical to Process Monitoring?

The significant food safety recalls that have occurred in the dairy processing industry this past year, ranging from Listeria outbreaks in ice cream to Cronobacter in infant formula, and the Food and Drug Administration’s* (FDA’s) recent publication of its revised Investigations Operations Manual draw attention to the criticality of inline process monitoring of bacterial risks, including the use of accurate aseptic inline sampling at milk pasteurizers and silo tanks to complement any conventional environmental monitoring practices.

“Aseptic sampling is often used in the collection of inline samples, environmental samples, product samples from bulk containers and collection of unpackaged product that is being collected for microbial analysis,” and that “aseptic sampling is critical to not only samples that will undergo microbiological analysis but also samples subject to chemical tests that might be altered by microbial activity.”

Source FDA’s revised manual

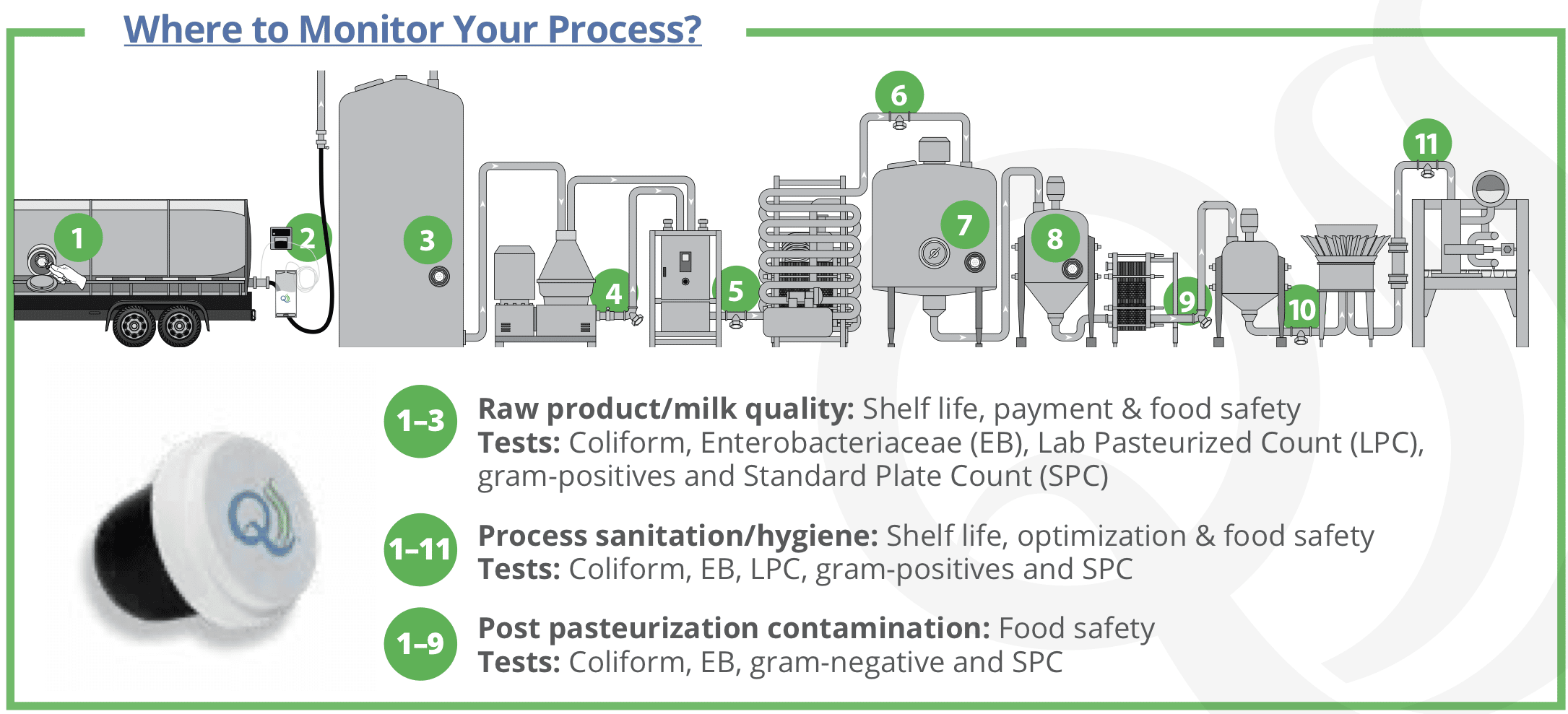

QualiTru understands that making decisions about why and where to sample product in the dairy and liquid food industry can be challenging, especially since there are not clearly defined procedures and responsibilities for sampling along the process chain. Quality managers, engineers, and farmers need to take a proactive approach to inline process monitoring and develop their own sets of sample collection standards for risk management. By being proactive, and not waiting to solve an issue or respond to a worst-case scenario, they can adopt systems that prevent risks, optimize their process, and strengthen quality.

Aseptic Inline Sampling Is Critical for Accurate Test Results

The method of sampling you choose is critical to the accuracy of your testing results. QualiTru’s unique sampling technologies are FDA approved and meet the FDA’s recommendation for aseptic sampling. Our simple-to-use aseptic inline sampling system means that the sampling equipment has been sterilized, thus mitigating the risk of introducing contamination into the sample.

Aseptic process monitoring involves installing a series of QualiTru stainless steel ports at critical control points (CCP) along the line. The QualiTru TruStream Septum, with either seven or 12 individual channels, is designed for single samples to be drawn from each channel — dramatically reducing the risk of cross-contamination. Each septum is made of high-quality, food-grade materials and features a label that clearly indicates which channels have been used. Once all channels have been used, simply dispose of the septum and replace it with a new one.

QualiTru collection units are equipped with a needle and tubing that provide a sterile fluid path for the milk collection. For continuous flow sampling, the collection unit tubing is configured to pass through an electric or portable peristaltic pump so that a representative sample can be collected over an entire process run. QualiTru’s aseptic sampling system, when coupled with aseptic technique for sample collection, greatly reduces the risks of inaccurate and unreliable test results. Use of aseptic technique during sampling requires procedures to reduce exposure to microorganisms and maintain objects and areas as free from contamination as possible. These steps to minimize risks are clearly outlined in our standard operating procedures (SOPs).

Challenges of non-aseptic sampling

- Micro ports: Micro ports are non-sterile grommets that may introduce contamination into the sample due to a lack of distinct channels. This may introduce gram-positive bacteria because the port is used more than once, and the product sits in the grommet over time.

- Valves: Valves require steam to kill all spore-forming bacteria. They also require additional energy and labor that may add up to 20 minutes per valve for proper clean-out-of-place (COP) or steam sterilization. Cleaning a non-sterile port requires disposing of the product that is in the valve to ensure it does not contaminate the sample. One customer estimated 50,000 Euros in cumulative loss due to the wasting of product from 15 seconds of flushing the valves across ten silos over a year’s time.

What Are Other Key Components for Effective Inline Process Monitoring?

It is critically important to test for gram-negative bacteria.

Gram-negative bacteria do not generally survive pasteurization, so detecting their presence in process monitoring samples is a warning sign of post-pasteurization contamination that can lead to spoilage and food safety issues. Their presence in pasteurized products indicates contamination somewhere along the process. The contamination level of gram-negative bacteria in pasteurized dairy products may be extremely low, often < 1 bacterium per gallon. Many gram-negative bacteria can grow rapidly at refrigerator temperatures, so the presence of even very small numbers of these ‘psychrotrophic’ bacteria may result in premature spoilage. More importantly, gram-negative bacteria could also indicate foodborne pathogens, such as Salmonella, E. coli, or Cronobacter. A positive post-pasteurization test requires corrective action.

Effective process monitoring is more than just total bacterial counts.

Biofilms are complex structures of microorganisms, typically comprised of minerals, proteins, and bacteria that attach to and build up on stainless steel surfaces. The bacteria can include those that survive pasteurization or are a result of post-pasteurization contamination.

Total bacterial counts are not the most effective method for detecting post-pasteurization contamination. Effective process monitoring must focus on the type rather than the number of bacteria.

Understanding the generation time of gram-negative psychrotrophic bacterial populations is critical for effective process monitoring.

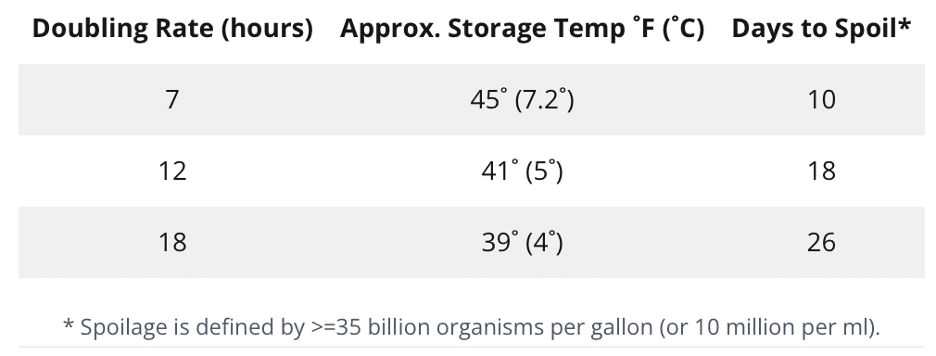

Even very small numbers of gram-negative bacteria in finished products can be significant because of their growth rate (also called doubling rate or generation time).

In pasteurized dairy products, the growth rate depends on the type of organism, availability of oxygen, storage temperature, and access to nutrients. Milk is a very nutrient-rich medium for bacterial growth. Psychrotrophs grow faster as temperatures warm, peaking at about room temperature. The graph below demonstrates the significance of the generation time of gram-negative psychrotrophic bacterial populations on milk spoilage, starting with one organism per gallon.

If You Cannot Measure Contamination Accurately, You Cannot Control It!

Accuracy in sampling and testing is key; aseptic inline sampling is a critical component for accuracy. Per the FDA’s latest recommendations, using the right combination of environmental and process monitoring helps ensure that farmers and processors are collecting accurate, representative data to mitigate risks and make corrections and improvements when needed.

We recommend using aseptic sampling techniques to evaluate raw milk quality at the start of any process to determine the presence of gram-positive bacteria that are capable of surviving pasteurization, as well as to detect any gram-negative bacteria that could be introduced after pasteurization or heat treatment and potentially impact final product safety and quality.

How can we help?

Do you have a contamination issue you are having trouble solving or would you like to discuss a proactive process monitoring plan? Complete this form to have one of our experts contact you for a FREE consultation. Or call us at (651) 501-2337 or email [email protected] to learn more and/or to discuss your needs.

As we like to say around here… Your Test Result Is Only as Accurate as Your Sample.

Additional resources about aseptic sampling and effective process monitoring:

- Free on-demand webinars

Monitoring Microbial Contaminations

Environmental Sampling: Is it Enough? - Related blog posts:

Heat-Resistant Psychrotrophic Bacteria and Their Effect on the Quality of Pasteurized Milk.)

Prevalence of Cold-tolerant Spore-forming Bacteria in the Milk Supply - Validation Studies

Bioprocess Tutorial: Reducing Contamination of the Septum, Controlling Entry of Bacteria Through The Sampling Port - Training

Site application schematics

Standard Operating Procedures (SOPs)

Have questions about aseptic and representative sampling for dairy plants?