The Effects of Gram-positive HRSF Bacteria on Fluid Milk Shelf Life (Part 2)

This is a guest post written by Neil Bogart, Executive Area Technical Support Coordinator of NA Food & Beverage for Ecolab Inc. He is a highly respected adviser in the food and beverage industry, providing troubleshooting, technical support, cleaning, and sanitizing solutions to the dairy, food, beverage, and bottled water markets. See the Author Bio at the end of the post.

Part 2 Topic: How do Gram-positive Heat Resistant Thermoduric/Psychrotrophic Spore Formers (HRSF) affect fluid milk shelf life?

The first article in this series, Raw Milk Micro Testing, focused on Gram-negative bacteria in raw milk with the Preliminary Incubation (PI) Count and Fresh Standard Plate Count (SPC) tests. In this second installment, I would like to discuss another classification of bacteria (Gram-positive HRSF Bacteria) that was not known as a major issue in fluid milk processing prior to the 2001 terrorist attacks in the United States.

What does the terrorist attack have to do with changes in the dairy industry?

Shortly after September 11, 2001, the U.S. Food and Drug Administration (FDA) and other federal agencies began developing a new program to protect the nation’s food supply from terrorist attacks, the Food Defense Program. It was based on the development of a risk vulnerability assessment model and its application to the food industry. To thwart a potential food defense risk, the fluid milk industry increased pasteurization temperature requirements from an average of 163ᵒF (72.8ᵒC) to the 170ᵒF (76.6ᵒC) range and tried to extend shelf life from 14 days to 16 days.

However, with the temperature increase, fluid milk shelf life mysteriously dropped significantly. Why? It has to do with the subject of this blog, Gram-positive bacteria. Before discussing them in detail though, it should be noted that as the food industry increased its awareness of food defense practices, the requirement to pasteurize at higher temperatures was reversed.

Fluid milk processing plants can again pasteurize at 161ᵒF (72ᵒC) for a minimum of 15 seconds, if the fat content of the milk is less than 10%, or total solids are less than 18%, and if there is no added sugar (Pasteurized Milk Ordinance (PMO), 2017).

So, back to the discussion of Gram-positive bacteria. Specifically, Gram-positive HRSF, e.g., Bacillus and Paenibacillus. Why did Gram-positive bacteria suddenly emerge as an issue for the dairy industry? Where do they come from? How do we test for them? Finally, how do we control the issue?

Why did Gram-positive HRSF bacteria suddenly emerge as an issue for the dairy industry?

As mentioned, the higher temperature pasteurization requirement and subsequent reduction in shelf life presented a mystery that needed solving. Solving this mystery starts with reviewing raw milk and pasteurized milk for quality and understanding the Gram-negative, Gram-positive, and HRSF loads.

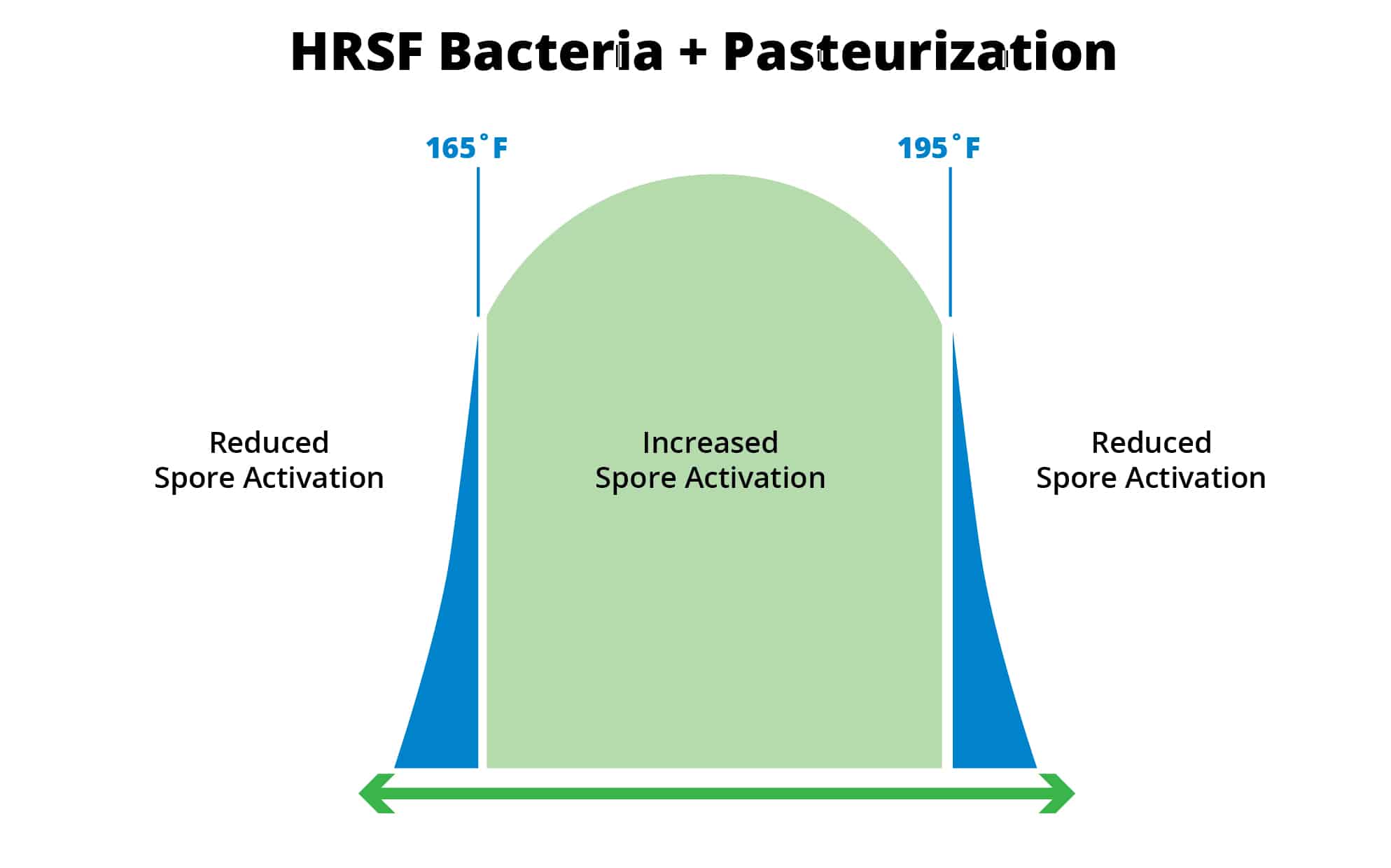

First, we need to understand some characteristics of these HRSF bacteria. The spores are activated by heat and because they are thermoduric are able to survive pasteurization. Their peak activation range is typically between 165 – 195ᵒF (73.9 – 90.6ᵒC). However, some of them are also psychrotolerant. They can grow at typical refrigerated temperatures of 45ᵒF (7.1ᵒC). Since they can grow at 45ᵒF (7.1ᵒC), the industry needs to include a method in their testing regime to understand how many of these psychrotolerant HRSF bacteria are in the raw and pasteurized milk.

As you can see from above, the industry started pasteurizing at the peak of the activation range for the HRSF bacteria after 9/11. If you pasteurize on either side of the peak, the number of spores that are activated is significantly reduced. It is almost a true bell curve.

Secondly, HRSF bacteria grow significantly slower than typical Gram-negative bacteria. You will usually not see product degradation with HRSF bacteria until after 16 days at 45ᵒF (7.1ᵒC). By comparison, typical Gram-negatives start deteriorating the quality of the milk after ten days and are unpalatable by 14 days at 45ᵒF (7.1ᵒC).

So, the fluid milk industry increased the pasteurization temperature into the peak activation range to thwart the food defense potential issue, and attempted to increase the desired shelf life of fluid milk from 14 to 16 days. Is it starting to make sense how these bacteria had previously been flying under the radar? Now remember, in the beginning, the industry had no clue what was causing the sudden shelf life decrease. However, the new regulations prohibited reducing the pasteurization temperature. The only thing the fluid dairy industry could do was to reduce shelf life back to 14 days. This cost the industry a lot of money.

Where do these Gram-positive HRSF bacteria come from?

Once we started to understand what was causing the issue, the Gram-positive HRSFs, we needed a quick way to test for them. While working for Randolph & Associates, Inc. (RAI) dairy consulting firm, Dennis Bogart and I developed the HR-3 Test. It was a quick qualitative test to determine the load of psychrotolerant HRSFs in the milk throughout the processing process from farm to bottle. When dealing with spores, it is all about the numbers; it’s all about bacterial load. They have always been there. The end game is reducing the number of active psychrotolerant HRSFs in the finished product.

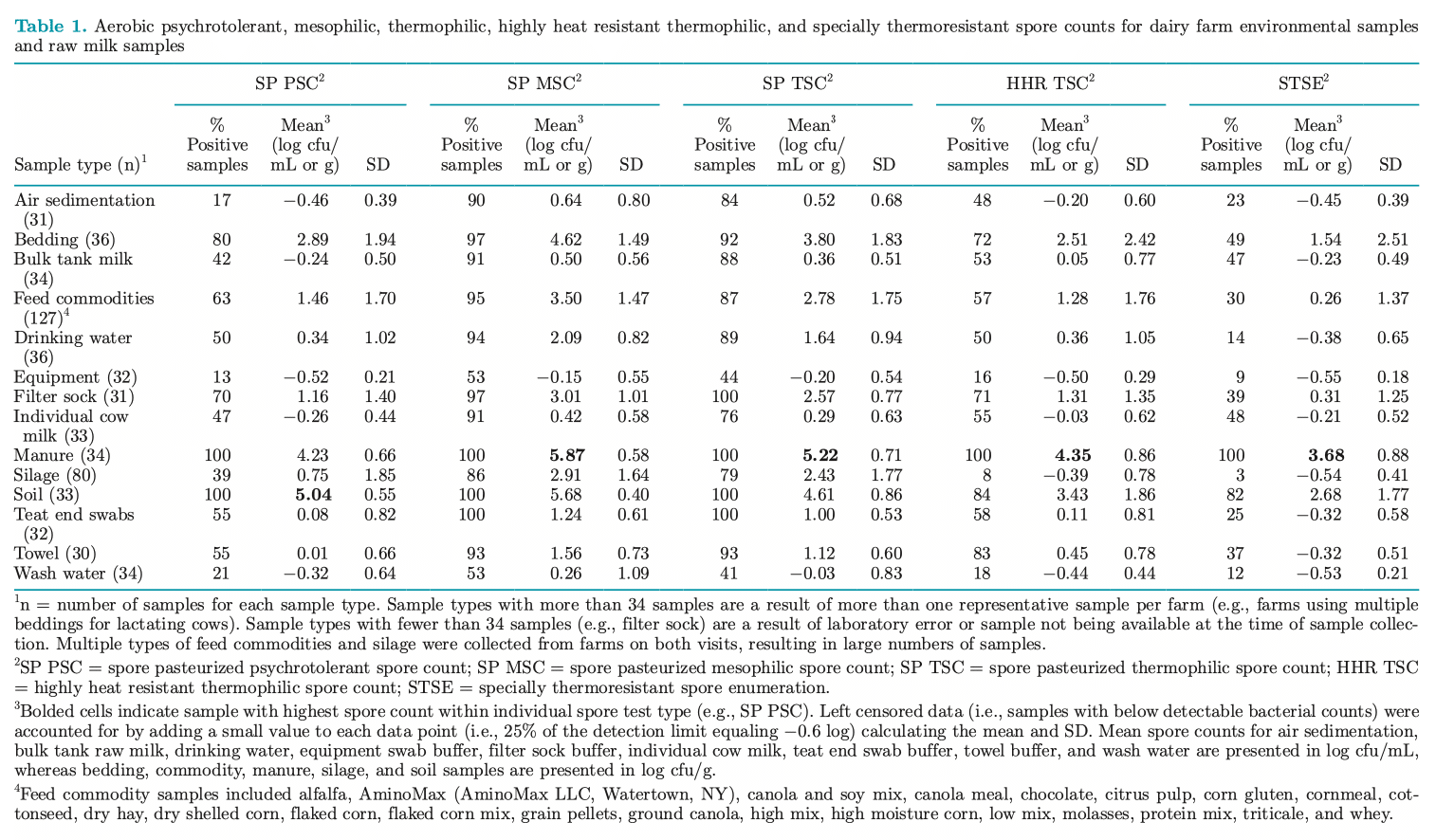

Then we turned our focus to where these Gram-positive HRSF bacteria come from. After a lot of testing of the milk throughout the journey from the farm to the bottle with the HR-3 Test, we found that the initial load of spores was coming from the farm; they are ubiquitous in nature. We determined that Good Milking Practices (GMP), which include wiping, stripping, and the use of a single-use towel, were critical for reducing the number of spores in the raw milk. But the question still loomed, where was the increased load of spores on the utters coming from? Cornell’s Milk Quality Improvement Program (MQIP) found that the teat end cleanliness and condition are the control points for the reduction of spore transmission from the bedding to the raw milk bulk tank (Martin, N. H., 2019). By implementing proper bedding practices and GMPs, the spore loads could be significantly reduced.

How do we test for these Gram-positive HRSF bacteria?

When testing for micro, you can use either qualitative or quantitative methods. As already mentioned, at RAI, we developed the HR-3 Test in the early 2000s (~2002 – 2004). It was a quick, 18-hour qualitative test to determine where the load of psychrotolerant HRSFs was in the milk. It helped us quickly determine at which point in the process, from farm to bottle, the spore numbers increased.

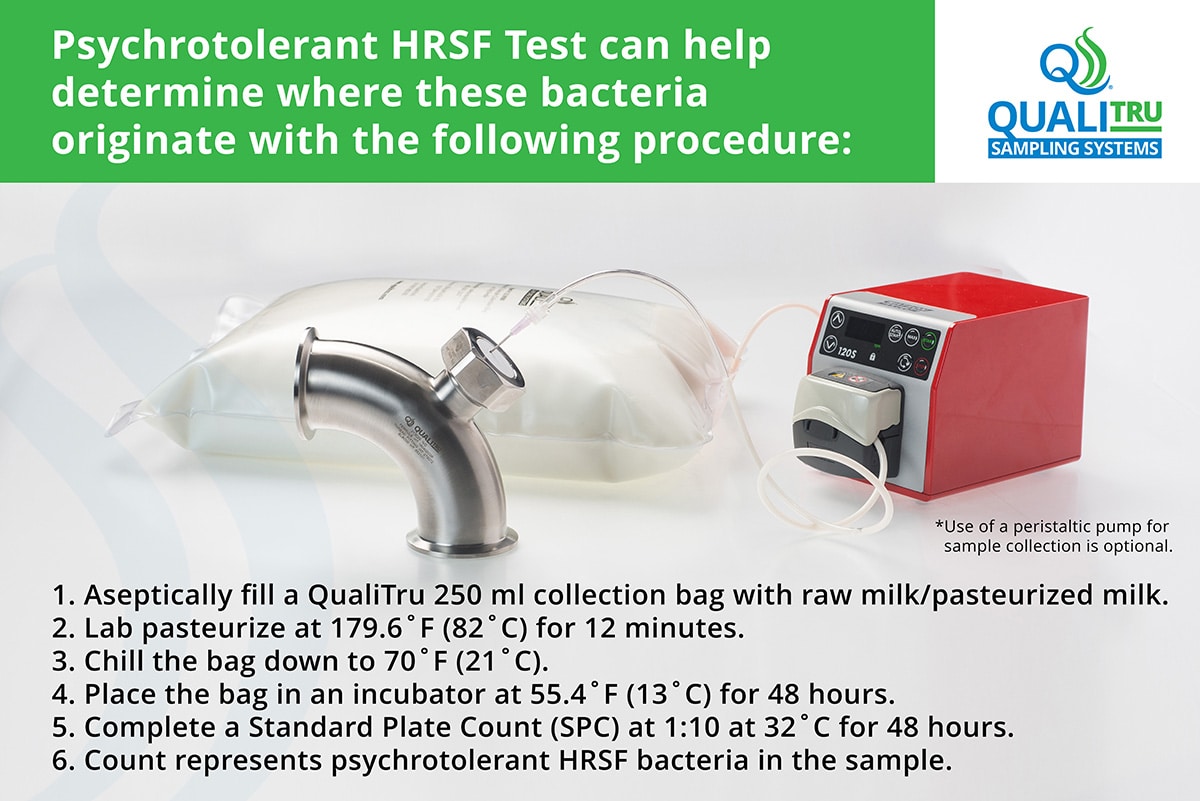

Since the HR-3 Test, there was a quantitative HRSF micro test developed for the review of psychrotolerant, mesophilic, and thermophilic spore counts by Cornell (Kent, D. J., 2016). Obtaining the psychrotolerant counts takes up to ten days. To speed up the psychrotolerant test turn time, Consolidated Lab Services (CLS) modified the test. The lab pasteurized sample is held at 55ᵒF (13ᵒC) for 48 hours and then plated for the determination of the psychrotolerant load. Utilizing the expedited psychrotolerant HRSF test, we found that the initial action level on individual farm loads, raw milk loads, high temperature short time (HTST) balance tank, and HTST discharge samples is ≥100 cfu/mL.

One last test that tends to be used is the Laboratory Pasteurized Count (LPC). The test was initially developed to determine the quantity of thermoduric bacteria that could survive vat Pasteurization, 145ᵒF (62.8ᵒC) for 30 minutes (PMO, 2017). The question is, how many dairies are still vat pasteurizing? If you are not vat pasteurizing, it is not recommended to use this test to determine the type of thermodurics that will survive your pasteurization process.

How do we control the issue of Gram-positive HRSF bacteria?

The number of spores in the raw milk and pasteurization temperatures have become critical to the extension of the shelf life of fluid milk beyond 14 days. There are three options in the control of the amount of viable psychrotolerant HRSF bacteria in the finished product.

Option 1, you can test every incoming load of raw milk for psychrotolerant HRSF bacteria. This is a historical test. You can use the data to build information on the routes and work with the routes that show higher counts to reduce the spore loads through Cornell’s bedding and GMP practices (Martin, N. H., 2019).

Option 2, reduce your pasteurization temperature outside the maximum activation range; e.g. 163ᵒF (72.8ᵒC) for 18 seconds. This option will reduce the number of spores activated through the pasteurization process.

Option 3, do both options 1 and 2, and add running the psychrotolerant HRSF bacteria test at the balance tank of the HTST and discharge of the HTST. This option is the best one for understanding the potential loads of spores coming through the process, reducing the amount that becomes viable, and if the HRSF bacteria are hung up in the HTST, inoculating everything run through the HTST.

Another option I have seen that helps reduce the number of spores at the HTST is adding in a bactofuge. A bactofuge can reduce the number of spores by up to 99%.

There’s still more to understand about shelf life.

So far, articles one and two have discussed raw milk Gram-negative bacteria contamination, Gram-positive, and Gram-positive HRSF bacteria. In the next article, we will dive into post-pasteurization contamination and what tests can help us better understand the potential for shelf life and how to proactively identify any issues before they become significant concerns. In the final article, we will bring all of these tests together to develop micro-program to support your desired shelf life and methods of processing.

Finding solutions for contamination issues can be challenging, frustrating, time-consuming, and sometimes costly! If you have a contamination issue you are having trouble solving or would like to discuss a proactive process monitoring plan, contact us at (651) 501-2337 or email [email protected] to have one of our experts contact you.

Additional resources related to dairy micro testing:

Free on-demand webinars:

Monitoring Microbial Contaminations

Previous blog posts:

Raw Milk Dairy Micro Testing (Part 1)

Prevalence of Cold-tolerant Spore-forming Bacteria in the Milk Supply

Heat-Resistant Psychrotrophic Bacteria and Their Effect on the Quality of Pasteurized Milk

Training

From Sampling Challenges to SAMPLING SOLUTIONS Infographic

Additional Videos

References: (1) Grade “A” Pasteurized Milk Ordinance, 2017, U.S. Department of Health and Human Services, Public Health Services, Food and Drug Administration, pg. 91. (2) Martin, N. H., Kent, D. J., Evanowski, R. L., Zuber Hrobuckak, T. J., and Wiedmann, M. 2019. Bacterial spore levels in bulk tank raw milk are influenced by environmental and cow hygiene factors. J. Dairy Sci. 102:9689-9701. (https://doi.org/10.3168/jds.2019-16304) (3) Kent, D. J., K. Chauhan, K. J. Boor, M. Wiedmann, and N. H. Martin. 2016. Spore test parameters matters: Mesophilic and thermophilic spore counts detected in raw milk and dairy powders differ significantly by test method. J. Dairy Sci. 99:5180-5191. (https://doi.org/10.3168/jds.2015-10283)