Maintaining the Quality of Pasteurized Fluid Milk

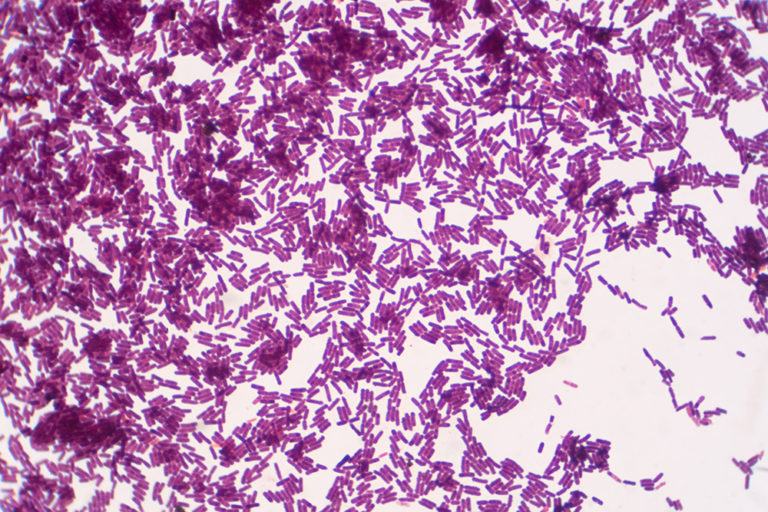

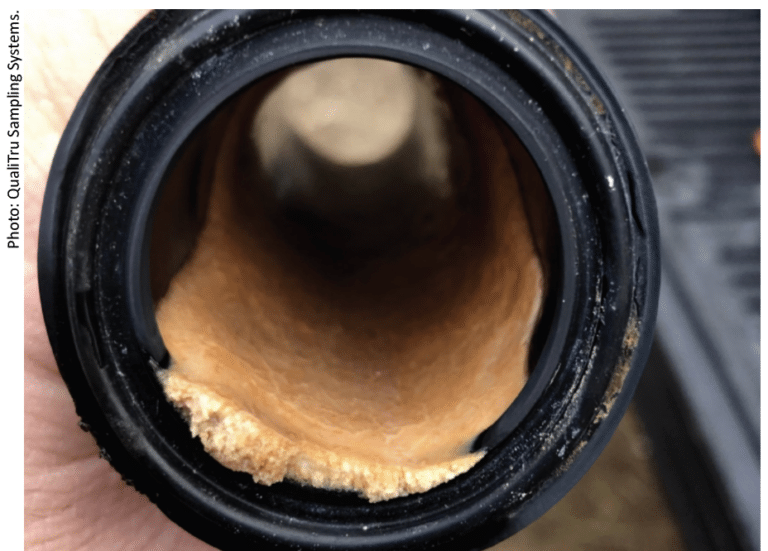

Quality control of pasteurized fluid milk can be complex and requires the understanding of microbial contamination, both in raw and processed milk. Aseptic and representative sampling plays an important role in monitoring raw milk quality and process monitoring for contamination within the dairy plant. Fluid milk (A commonly used term in the industry for milk…